Video

1 / 4

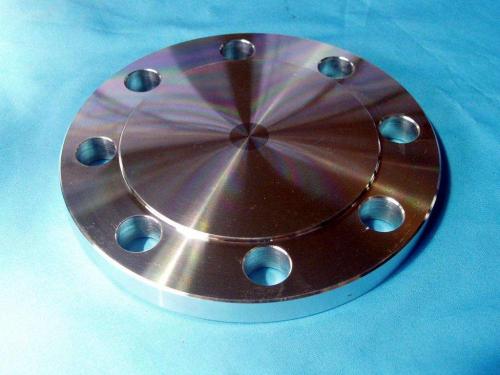

ASME B16.47 Series B Flanges

| Model No. : | P-Flanges |

|---|---|

| Brand Name : | Bangdong |

| Standard : | BSW |

Product description

ASME B16.47 Series B Flanges

Bangdong Supply LWN Forged Flanges,Alloy Steel Forged Flanges,SS 316L Flanges.The double submerged arc weld (DSAW) process is similar to that of the ERW process in that coils of carbon steel are unrolled in a continuous ribbon. As the DSAW method of manufacturing is typically used for larger diameter pipe, the method of roll forming the skelp is similar to but not exactly like that of ERW. DSAW pipe is typically either pyramid rolled (three angled OD rolls in the shape of a pyramid form the pipe) or rolled using the U-O-E process (skelp is first subject to a "U" shaped press, followed by a "O" shaped press). The most prominent difference between ERW and DSAW carbon steel pipe is the longitudinal weld. The DSAW arc weld is submerged in a flux media to keep the weld from being exposed to ambient contaminants. Also, both the OD and the ID of the pipe is welded, typically at separate times creating a situation where one weld consumes the other creating a higher quality weld. DSAW carbon steel pipe is easily distinguishable due to its prominent and consistent ID and OD weld seam. Common DSAW specs include; API5l, A252, and A139.

Packing: No Fumigate or Fumigate Plywood/Wood Pallet or Case

Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

Forged steel Flange are perfectly finished with precision using the latest machinery.

Dimension to be in accordance with JIS ANSI DIN BS standard accordingly.

Forged flange is defined as a plate type device, normally round, that is attached to the end of a pipe, fitting, valve or other object to facilitate the assembly and disassembly of a piping system.

Forged steel flanges made of carbon steel or stainless steel, the materials conform to the JIS, ASTM A182,A105, DIN17100 ST-2 and BS standard. Dimension to be in accordance with JIS ANSI DIN BS standard accordingly.

The flanges are suitable for connection of steel pipes conveying mediums such as steam, oil, air and water. They are widely used in Chemical industry and Shipbuilding . And the flanges are suitable for welding.The flanges mainly include Welding Neck, Blind, Slip-on, Lap-Joint, Socket,Reducing and Plate type.

Size available: 1/2"--72"(DN15-DN1800).

Forged steel flanges made of carbon steel or stainless steel, the materials conform to the JIS, ASTM A182,A105, DIN17100 ST-2 and BS standard.

In the production, press the mass of the forging parts, the quantity of the batch of different forging methods. Free forging productivity is low, processing surplus is large, but the tool is simple, universality is large, so it is widely-

Forged steel flanges are made in seven primary ratings:

Asme B 16.5 Class 150 lb 400 lb 900lb 2500lb 300lb 600lb 1500lbcutting and then continue to beat, to eliminate the ingot in the segregation, loose and other defects. Price and mechanical properties are higher than ordinary casting flange a grade. The flange is a part that connects the pipe with the pipe and the valve, is connected to the pipe end. It is also used for the flange on the equipment inlet and outlet.

Forged steel flanges are made in seven primary ratings:

Asme B 16.5 Class 150 lb 400 lb 900lb 2500lb 300lb 600lb 1500lbcutting and then continue to beat, to eliminate the ingot in the segregation, loose and other defects. Price and mechanical properties are higher than ordinary casting flange a grade. The flange is a part that connects the pipe with the pipe and the valve, is connected to the pipe end. It is also used for the flange on the equipment inlet and outlet.

face type:Flat Face, Raised Face, Ring Joint Face, Lap Joint Face, Male Face, Female Face, Tongue & Groove Face

Type:

Weld Neck Flange, Slip On Flange, Blind Flange, Socket Welding Flange, Thread Flange, Reducing Flange,Spectacle Blind Flange, Orifice Flange

Video

Send your inquiry to this supplier