1 / 1

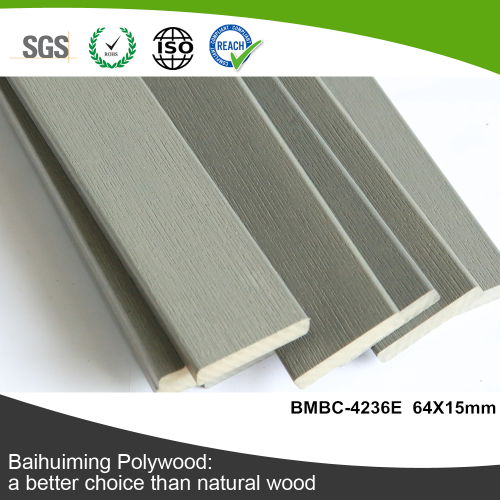

Anti-UV Polywood Outdoor Flooring for Wood Plastic Composite Furniture (BMBC-4236E)

Get Latest Price

Send Inquiry

| Model No. : | Polywood Board BMBC-4236E |

|---|---|

| Brand Name : | BM |

Foshan Shunde District Baihuiming Furniture Fittings Co., Ltd.

You might also like

Product description

Anti-UV Polywood Outdoor Flooring for Wood Plastic Composite Furniture (BMBC-4236E) About Us * Experience: We have been in WPC board for more than 13 years. Monthly output is 200-250 metric tons/month.

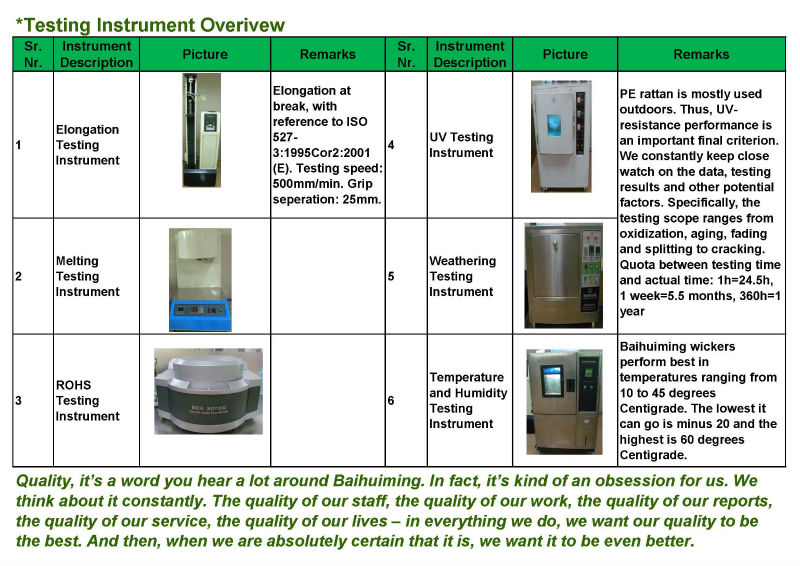

Anti-UV Polywood Outdoor Flooring for Wood Plastic Composite Furniture (BMBC-4236E) About Us * Experience: We have been in WPC board for more than 13 years. Monthly output is 200-250 metric tons/month.* In-house Testing: We have all kinds of in-house testing machines including but not limited to ROHS, Melting, Tension, UV, Humidity and Color Variation Testers.

* R&D: We are manpowered by one of most professional WPC R&D teams of China. We enable customers to have all kinds of colors, effects, textures and glossiness within deadlines.

* Certificates: We manufacture WPC board according to ISO2001:2000 quality control system guidelines.

* Subsidiary: We have another 3 WPC board factories which are located in Shunde, Tianjin and Linhai, Zhejiang. About WPC Board * General Information Many engineers and companies have been convinced by the advantages of this bio-composite, resulting in the emergence of many new mixtures and applications. The WPC market is experiencing high growth rates worldwide. The overall volume of WPC on the North-American market in 2005 is estimated at 700,000 tons.

In 2006 China produced about 75,000 tons of WPC. The production volume in 2007 is estimated to amount to roughly 100,000 tons in Europe and to some 30,000 tons in Germany. Experts anticipate annual growth rates of 20 to 30 per cent. New application areas are expected in particular for injection-molded products, for example in the automotive and furniture industries. *WPC Applications: We have 2 subsidiaries for WPC slat processing which enable us to finish semi-products and finish products. Here are the applications for them:

* Features Texture/surface: Glossiness Mold: High-tech Mold cost: free of charge for existing style, new model will be charged accordingly, the cost range is $1000-$2000. Mold lead time: around 7-10 days. Advantage: No painting or glue required, Anti-slip, less cracking and less warping, UV-resistant, Dimension-stable, Weather-resistant, Moisture-resistant, Pest and fungus-free, Environment-friendliness: non-toxic, recyclable and ecologically sound. WPC slat size overview:

* Features Texture/surface: Glossiness Mold: High-tech Mold cost: free of charge for existing style, new model will be charged accordingly, the cost range is $1000-$2000. Mold lead time: around 7-10 days. Advantage: No painting or glue required, Anti-slip, less cracking and less warping, UV-resistant, Dimension-stable, Weather-resistant, Moisture-resistant, Pest and fungus-free, Environment-friendliness: non-toxic, recyclable and ecologically sound. WPC slat size overview:  Color Collection Overview:

Color Collection Overview:  * Material Information Raw Material: PS-1 Benzene, PS GPPS, Foaming Agent, Anti-UV and Anti-Oxidizer UVA: Ultraviolet-Anti Coloring Materials: Color Master Batch and Color Powder, high concentration of pigments, good dispersing agency, heat-resistance * Tolerance 1. Length: 3-5mm 2. Width: 3-5mm 3. Thickness:3-5mm 4. Density: 3-5mm * Testing Information 1. ROHS 2. High Temperature Resistance 3. Low Temperature Resistance 4. UAV Test

* Material Information Raw Material: PS-1 Benzene, PS GPPS, Foaming Agent, Anti-UV and Anti-Oxidizer UVA: Ultraviolet-Anti Coloring Materials: Color Master Batch and Color Powder, high concentration of pigments, good dispersing agency, heat-resistance * Tolerance 1. Length: 3-5mm 2. Width: 3-5mm 3. Thickness:3-5mm 4. Density: 3-5mm * Testing Information 1. ROHS 2. High Temperature Resistance 3. Low Temperature Resistance 4. UAV Test  * Customizations 1. Width 2. Thickness 3. Texture 4. Glossiness 5. Finish Color 6. Shape 7. Density 8. Melting Point 9. Viscosity 10. Tensile and Flexural Strength 11. Impact strength 12. Elongation at break 13. Weather resistance 14. Insect resistance * Machine Overview 1. Extruding Machine 2. Mixing Machine 3. Packing Machine 4. Traction Machine 5. Crusher 6. Scratching Machine 7. Embossing Machine 8. Cutting Machine * Quality Control 1. IQC (Incoming Quality Check) 2. IPQC (In-Process Quality Check) 3. OQC (Out-going Quality Check) 4. FQC (Final Quality Check) 5. Applied QC Method: AQL (Acceptable Quality Level) 6. Major 6.5, Minor 1.0 * Acceptable Quality Levels

* Customizations 1. Width 2. Thickness 3. Texture 4. Glossiness 5. Finish Color 6. Shape 7. Density 8. Melting Point 9. Viscosity 10. Tensile and Flexural Strength 11. Impact strength 12. Elongation at break 13. Weather resistance 14. Insect resistance * Machine Overview 1. Extruding Machine 2. Mixing Machine 3. Packing Machine 4. Traction Machine 5. Crusher 6. Scratching Machine 7. Embossing Machine 8. Cutting Machine * Quality Control 1. IQC (Incoming Quality Check) 2. IPQC (In-Process Quality Check) 3. OQC (Out-going Quality Check) 4. FQC (Final Quality Check) 5. Applied QC Method: AQL (Acceptable Quality Level) 6. Major 6.5, Minor 1.0 * Acceptable Quality Levels  * Possible Quality Problems of WPC Board 1. Screwing position breakage 2. Deformation 3. Color Variation 4. Splitting 5. Evenness 6. Bubble 7. Elongation 8. Flexural Strength 9. With full awareness of above possible problems, our QCs of all stages will watch these problems very closely and conduct all technical actions to avoid these problems.

* Possible Quality Problems of WPC Board 1. Screwing position breakage 2. Deformation 3. Color Variation 4. Splitting 5. Evenness 6. Bubble 7. Elongation 8. Flexural Strength 9. With full awareness of above possible problems, our QCs of all stages will watch these problems very closely and conduct all technical actions to avoid these problems.  * Warehouse Conditions of WPC Board 1. Shady 2. Cool 3. Dry 4. Dust-free

* Warehouse Conditions of WPC Board 1. Shady 2. Cool 3. Dry 4. Dust-free  * Maintenance of WPC Board 1. Dust collecting with a mini vacuum cleaner 2. Brushing with a brush or wet rag 3. Mild soap and water or slightly salty water 4. Away from fire * Supply Capacity Information *Production Lead Time: 1. High Season (September to April): 20-30 days/10 metric tons 2. Low Season (May to August): around 15-20 days/10 metric tons *Sampling: 1. Lead Time: 5-7 days 2. Cost: Free of charge (only for exiting style) * MOQ of WPC Board At least, 1 metric ton. * Payment Terms: 1. 30% down payment before production and balance before shipment. 2. For established customers, we will offer more favorable payment terms. 3. Currencies of USD, EUR or HKD are both acceptable. 4. We can offer different pricing of FOB, CIF and C&F. 5. L/C is acceptable. * Production Flow

* Maintenance of WPC Board 1. Dust collecting with a mini vacuum cleaner 2. Brushing with a brush or wet rag 3. Mild soap and water or slightly salty water 4. Away from fire * Supply Capacity Information *Production Lead Time: 1. High Season (September to April): 20-30 days/10 metric tons 2. Low Season (May to August): around 15-20 days/10 metric tons *Sampling: 1. Lead Time: 5-7 days 2. Cost: Free of charge (only for exiting style) * MOQ of WPC Board At least, 1 metric ton. * Payment Terms: 1. 30% down payment before production and balance before shipment. 2. For established customers, we will offer more favorable payment terms. 3. Currencies of USD, EUR or HKD are both acceptable. 4. We can offer different pricing of FOB, CIF and C&F. 5. L/C is acceptable. * Production Flow  * FAQ (Frequently Asked Questions) 1. What can I use WPC slats for? WPC slats are widely applied in following categories: outdoor furniture, park bench, swimming pool, decking, railing, walling, paneling, fencing and planters. 2. Is the WPC furniture easy to move? Yes, it is less heavy than natural wood. Normally one person can move the chairs easily and 2 people are required to move a table, just like furniture made of other materials. We will state this in the instruction manual accordingly. 3. What is I don’t want to buy WPC slats from you but the entire table top or bench top? If you want to order entire table top or bench top in WPC, we are enabled to process the order since have our subsidiaries of processing the slats into semi-products and finish products. 4. Is it UV Protected? Yes. Baihuiming products are highly protected against UV radiation. Please note however UV stabilization is of the plastic component of the product and does not have a great affect on the fading characteristics. 5. Will it warp? Baihuiming decking will not warp provided it is used and fixed in accordance with fixing instructions. Baihuiming mini board can in some circumstances, show slight deflection between uprights. 6. Does it splinter? The composition of Baihuiming products means that they will not splinter. This makes them ideal for small children. 7. Does it fade? Baihuiming products are in high quality, it is colorfast. Even in high temperature, the color is still stable. But in long time under high temperature, it will be slightly faded. 8. How to clean? A simple sweep of the deck area will generally prevent build-up of dirt and grime (or even leaves) that can lead to unwanted marks, stains and mould on your deck. Gaps between the boards should also be cleared of debris should this occur. 9. How can I achieve a trouble-free installation of WPC decking?

* FAQ (Frequently Asked Questions) 1. What can I use WPC slats for? WPC slats are widely applied in following categories: outdoor furniture, park bench, swimming pool, decking, railing, walling, paneling, fencing and planters. 2. Is the WPC furniture easy to move? Yes, it is less heavy than natural wood. Normally one person can move the chairs easily and 2 people are required to move a table, just like furniture made of other materials. We will state this in the instruction manual accordingly. 3. What is I don’t want to buy WPC slats from you but the entire table top or bench top? If you want to order entire table top or bench top in WPC, we are enabled to process the order since have our subsidiaries of processing the slats into semi-products and finish products. 4. Is it UV Protected? Yes. Baihuiming products are highly protected against UV radiation. Please note however UV stabilization is of the plastic component of the product and does not have a great affect on the fading characteristics. 5. Will it warp? Baihuiming decking will not warp provided it is used and fixed in accordance with fixing instructions. Baihuiming mini board can in some circumstances, show slight deflection between uprights. 6. Does it splinter? The composition of Baihuiming products means that they will not splinter. This makes them ideal for small children. 7. Does it fade? Baihuiming products are in high quality, it is colorfast. Even in high temperature, the color is still stable. But in long time under high temperature, it will be slightly faded. 8. How to clean? A simple sweep of the deck area will generally prevent build-up of dirt and grime (or even leaves) that can lead to unwanted marks, stains and mould on your deck. Gaps between the boards should also be cleared of debris should this occur. 9. How can I achieve a trouble-free installation of WPC decking?Consult local building codes prior to installation.

Familiarize yourself with installation instructions.

Ensure you have all the tools and materials needed- as listed in the instruction sheet. 10. Are your WPC slats certified? Yes, our WPC slats are tested and certified by SGS, one of the most reputable and renown testing companies in the world. Come and ask us for a copy of the testing report. You will know much more technical performance of our products. *Company Overview:

*Customers using our WPC Slats:

*Customers using our WPC Slats:  * Our markets of WPC products:

* Our markets of WPC products:

Send your inquiry to this supplier

Send Inquiry