1 / 5

Aluminum foil core Aluminum Sleeve Roll Forming Machine

| Model No. : | TG-0135 |

|---|---|

| Brand Name : | TG |

| Application : | Other |

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

Aluminum Sleeve Roll Forming Machine is also called Aluminum foil core Roll Forming Machine, Aluminum foil roller Roll Forming Machine. The aluminum foil core produced by the Aluminum Sleeve Roll Forming Machine is mainly used for is suitable for winding, storing and transporting various optical films, high-performance films, metal foils and high-grade papers. The technology of Aluminum Sleeve Roll Forming Machine is international initiative and high performance environmental protection product, instead of paper core. Aluminum foil core Roll Forming Machine has high strength, no deformation, stable physical performance, effectively prevent aluminum deformation damage to the packaging film. The Aluminum foil roller Roll Forming Machine has high machining accuracy and good surface finish, which can improve the utilization ratio of the membrane. Due to the lack of smooth surface, the traditional shaft tube is filled and filled with packaging film. Aluminum foil core Aluminum Sleeve Roll Forming Machine is resistant to high temperature and impact. Not affected by environmental factors such as humidity and acidity.

1. Profile Drawing and Products for Reference

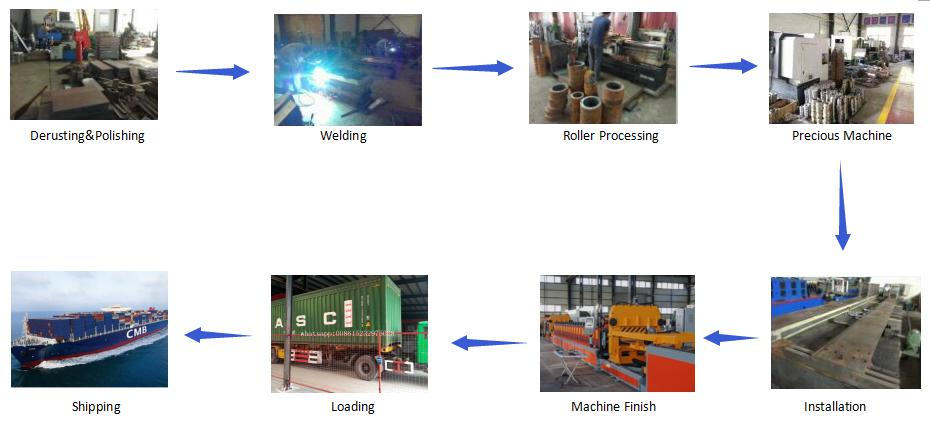

2. The Chart of Process Flow

Decoiler - Marking - Forming Stage - Welding Stage - Cooling System- Sizing Stage - Straightening Stage - Fixing Length - Cut off Stage and Other Processes.

3. Machine Overview

4. Scene application

5. Customer

6. Loading

7. Installation and training:

1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual to teach you to install and operate.

3. COST OF INSTALLATION:

The buyer should pay the installation charges (USD 80 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Our main products include Stud Track Roll Forming Machines, Steel Frame Forming Machines, Purlin Roll Forming Machines, Welded Pipe Making Machines, Highway Guardrail Roll Forming Machines, Metal Expanded Mesh Production Lines and so on. If you have any further question of our Cold Roll Forming Machine, please feel free to contact me.Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier