1 / 5

Aluminium roofing sheet corrugating machine

| Model No. : | DX corrugated |

|---|---|

| Brand Name : | DIXIN |

| Color : | Blue |

Product description

Aluminium roofing sheet corrugating machine

Dixin automatic a very convenient machine building material making machinery steel sheet roof & Wall panel forming machine

In the current industry leader in roll forming machine, can according to the requirements of customers design and production, we have more than 10 years of production experience, and products sold to all over the world, especially in South Asia, southeast Asia, the Middle East, Africa and South America, very popular, and receives the customer the consistent high praise, has many long-term cooperation customers, we pursue the quality of the service and machine experience, the constant pursuit of innovation and high-tech research and development, is committed to customers reduce costs, our sales mode of production is high, low profit.

Product Description

Technical parameters:

(1) Processing material: aluzinc/galvanized steel/colored steel coil

(2) Material thickness: 0.3-0.8mm

(3) Main motor power: 4 kw

(4) Pump power: 4kw

(5) Shaft diameter: 75mm

(6) Forming steps: 15 steps.

(7) Roller material: 45# forged steel, with hard chrome plating

(8) Main frame: 350H steel

(9) Medium plate thickness: 18mm

(10) Control systerm: PLC computer control with inverter

(11) Power supply: 380V, 3 Phase, 60Hz or as your requirement

(12) 0veral sized:about 6800mm*1500mm*1500mm

1) Payment: 30% T/T prepaid, and pay the balance before shipping.

2) Delivery time: 30 working days.

3) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

4) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

5) Installation and training:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and CD to teach you to install and operate.

c. COST OF INSTALLATION:

The buyer should pay the installation charges (USD 80 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

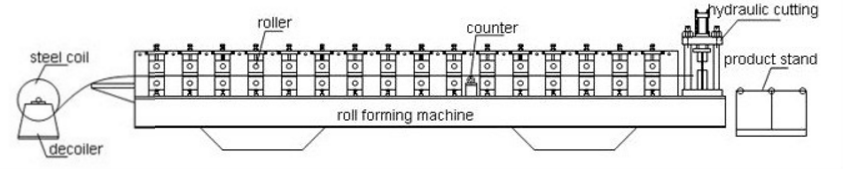

Work Flow:

Manual decoiler-Roll forming machine-PLC control-Hydraulic system -Post cut-Stacking

If you have specific requirements, just tell me!

| No. | ||

| 1 | Suitable material | color steel sheet, galvanized steel sheet, aluminium sheet |

| 2 | Material width | 1250mm or as your required |

| 3 | Material thickness | 0.3-0.8 or as your required |

| 4 | Working speed | 8-12m/min, can be 20-25m/min |

| 5 | Main motor power | 5.5kw with cycloidal with reducer |

| 6 | Hydraulic pump power | 4kw |

| 7 | Electrical control system | PLC control system with inverter |

| 8 | Shaft diameter | 75mm |

| 9 | Roller station | 15 rows, depend on your panel profile drawing |

| 10 | Roller | high grade 45# steel, hard chrome plating |

| 11 | Working time | 24 hours |

| 12 | workers | 1-2 only |

| 13 | Cutting head material | Cr 12 mould steel with quenched treatment |

| 14 | Voltage | 380V 3Phase 50Hz or as your required |

| 15 | Weight | 3.5T |

| 16 | The machine size | 7000mm*1500mm*1500mm |

Company Introduction :

Our enterprise, Cangzhou Dixin Roll Forming Machine Co., Ltd, as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers` trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc.

Warmly welcome to China to visit our factory and select the machines you need. Our address, Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China

We can professional manufacture all kinds of roll forming machines. For example:

Hydraulic decoiler, roof and wall panel sheet roll forming machne, C/Z purlin roll forming machine, glazed tile roll forming machine, JCH hidden roof panel roll formin machine, sandwich panel production line, keel molding equipment, door frame roll forming machine, roller shutter making machine, arch bending machine, hydraulic shearing machine, simple slitting machine, etc.

We can customize your panel profile drawing well.

We have the most excellent technician.

Send your inquiry to this supplier