Video

1 / 4

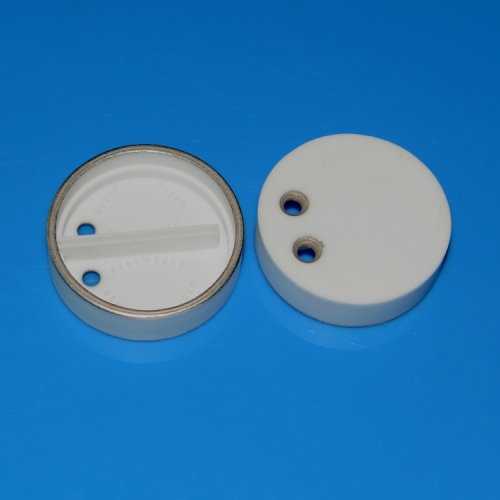

Alumina Metallized Ceramic Insulator for Brazing Assembly

Options:

- Alumina Metalized Isolator

- Industrial ceramic parts

- Mo/Mn metallization + Nickel plating

- High brazing strength, high gas tightness

- Used in ceramic to metal seal technology

- Metalized Ceramics

| Model No. : | Customized |

|---|---|

| Brand Name : | Jinghui Ceramics |

| place of origin : | China |

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

Why do ceramics metalized?

Technical ceramics offer signicantly different strengths in comparison with metals, in order to combine the strength of both materials, sometimes, it has to braze ceramic to metal together to use in the practical applications. But the critical problem of brazing between ceramic to metal is the wettability, it's impossible to braze ceramic to metal directly. In order to overcome the brazing problem, a kind of technology, called as "ceramic metallization" born. Metallization process is apply " molybdenum / managnese" " Tungsten" on the certain section of ceramic components, then cure it under high temperature in reduced atmosphere furnace, then the metal will be coated tightly on surface. Most of time, in order enhance the wettability at brazing process, an additional metal layer is needed, such as nickle plating, gold plating and so on.

Jinghui industry Ltd have been focus on supply variety of metallized ceramic isolator over 13 years, all metallized ceramic components we supplied have proven what:

1.Excellent metallized-seal strength and hermeticity 2.Proven in extreme-duty applications worldwide

3.Consistent performance with all common-braze alloys 4.High-volume production capacity and large-part-size capability

Typical application of metalized ceramics

It's widely used in Feed-through insulators, Headers,High-power receptacles, Insulating discs, Insulator rings and cylinders,Power switches, Traveling wave tubes,Vacuum interrupters,Windows,Power grid tubes,X-ray tubes and so on.

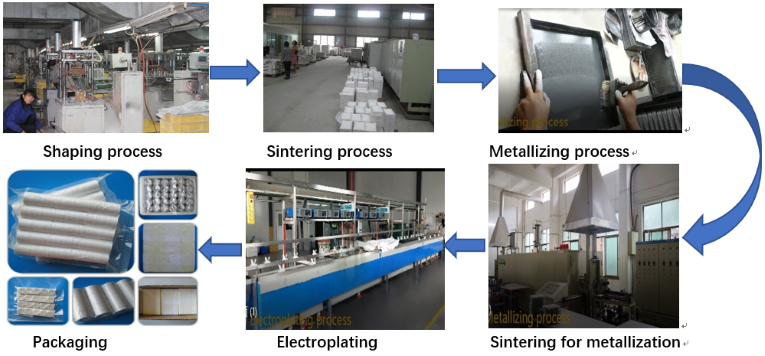

Main Manufacturing Flow Chat

We have a complete comprehensive of production equipment for metallized ceramics, including shaping of ceramic parts, sintering, machining and electroplating.

Established in 2008, Jinghui Industry Ltd. View More

Video

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier