Video

1 / 1

advanced vertical fluidized bed jet milling machine

Options:

- Feeding particle size(mm)<3

- Product particle size(d97:um)2~75

- Production capacity(kg/h)5-2500

- Air consumption (m3/min):3-40

- Air pressure:0.7~0.85

- Installed power:30-298

| Model No. : | QLMA-10 |

|---|---|

| Brand Name : | Jingxin |

| Capacity (kg/h) : | kg/h |

Weifang, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

INFORMATION DETAILS

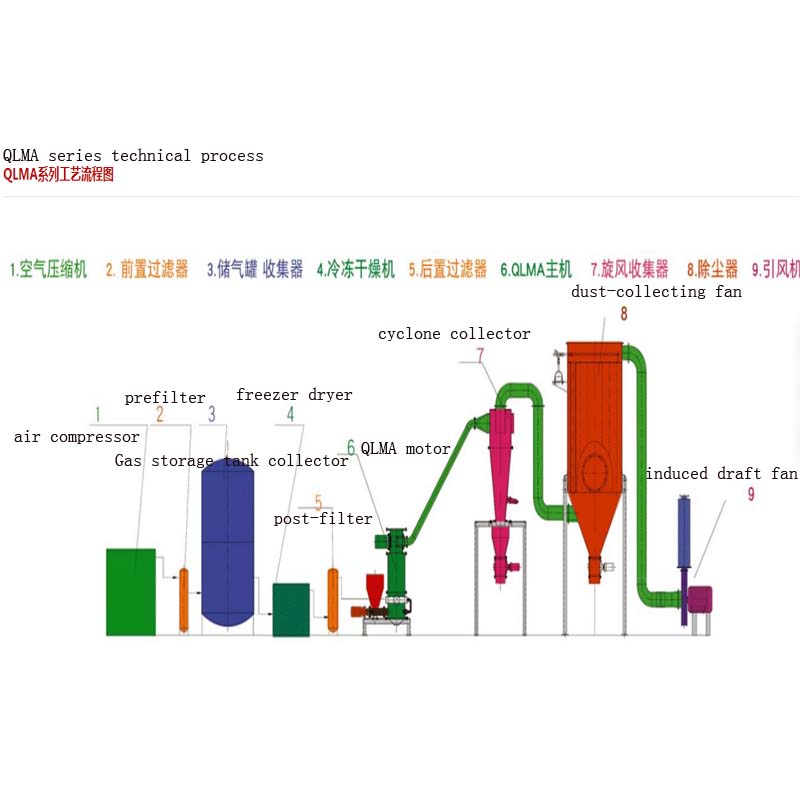

Dry compressed air is filtered through the high-speed laval nozzle jet into the crushing chamber, drive material in high pressure air flow intersection repeated collision, friction and crushing, after crushing under the action of negative pressure fan, the thickness of the mixture to the district of classification, in the high speed rotating grading turbine under the action of the strong centrifugal force, make the thickness of material separation, The material that meets the particle size requirements is collected by the grading wheel into the cyclone separator and dust collector, and the particle material is dropped to the crushing area for crushing.

EQUIPMENT CHARACTERISTICS

Suitable for all kinds of materials with MOHS hardness below 9, especially for high hardness, high purity and high value added materials.

● Particle acceleration technology breakthrough, greatly improve the crushing efficiency, reduce energy consumption, over the crushing of small particle shape is good, narrow particle size distribution and no large particles, product particle size D97:2-75 microns between arbitrary adjustment.

● In the crushing process, due to the sharp expansion of the air flow, the air flow temperature is reduced, especially suitable for the crushing of heat sensitive, low melting point, sugar and volatile materials.

● Materials collide with each other for crushing, different from mechanical crushing relying on dao pieces or hammer on the impact of the material crushing, so the equipment has no wear and the product purity is high.

● It can be used in series with multi-stage classifier to produce products with multiple particle size segments at a time.

● Compact structure, easy disassembly and cleaning, smooth inner wall without dead Angle.

● The whole system is closed and crushed, no dust, low noise, clean and environmentally friendly production process.

● The control system adopts program control, easy to operate.

● It can mix and crush several kinds of materials; Variable combination structure, compact structure, one machine multi-purpose.

● Non-metallic ore powder processing: kaolin, talc powder, graphite, light calcium carbonate, mica, vermiculite, spinel, attachorite, wollastonite, brucite, bentonite, etc.

● High hardness material powder processing: silicon carbide, corundum, zirconia, boron carbide, tourmaline, silicon oxide, alumina, garnet, zircon sand, diamond, etc

● Chemical powder processing: aluminum hydroxide, silica gel, white carbon black, wood powder, epoxy resin, toner, foaming agent, magnesium hydroxide, cellulose, molybdenum trisulfide, antimony trioxide, titanium dioxide, alumina, dyes, pigments, etc

● Pesticide powder processing: carbendazim, methyl tobuzin, herbicide powder, insecticide powder, fungicide powder wettable powder, etc

● Pharmaceutical powder processing: green tea, salvianthus miltiorrhiza, pearl powder, terrapin powder, panax notoginseng, west green fruit, nimodipine, fenofiate, ibuprofen, bismuth nitrate, cortisone, penicillin, pollen, pearl powder, nimodipine equal

● Food powder processing: barley flour, food calcium, coral reef, barley seedlings, gum sugar powder, etc

● Pigment powder processing: iron oxide, chromium oxide, phthalocyanine, cadmium red, cadmium blue, etc

● Metal material powder processing: zinc powder, aluminum powder, magnesium powder, tin powder, copper powder, tantalum powder, tin lead alloy powder, ferro molybdenum powder, etc

● Battery material powder processing: lithium cobaltate, cobalt oxide, lithium manganate, manganese dioxide, lithium nickel cobaltate, lithium carbonate, coke, graphite, lithium iron phosphate, asphalt, composite materials, etc

● Flame-retardant material powder processing: magnesium oxide, magnesium carbonate, zinc oxide, zinc borate, magnesium hydroxide, etc.

● Other material powder processing: rare earth materials, magnetic materials, ceramic materials, refractory materials, electronic materials, etc.

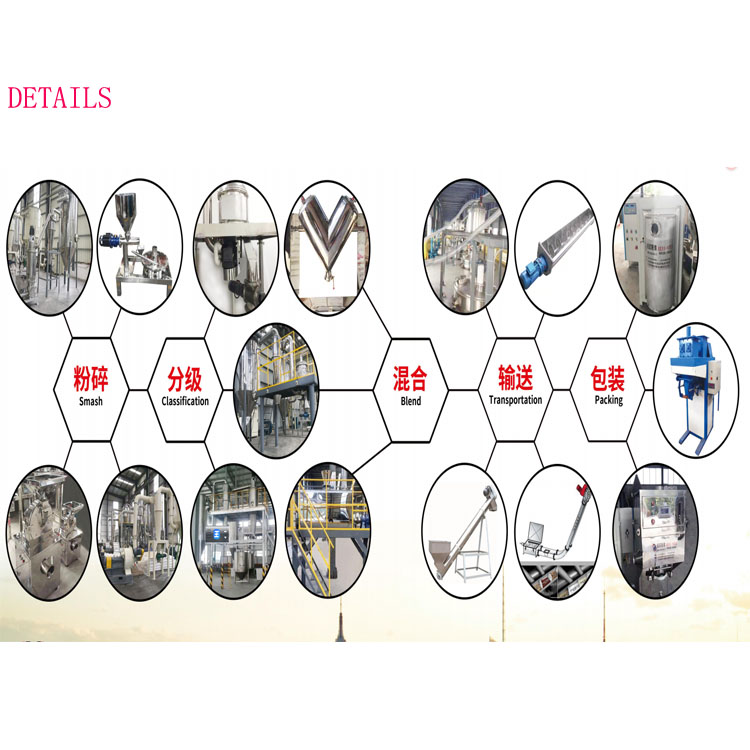

Our ain products are air jet mill, horizontal jet mill , vertical jet mill , lab jet mill, plat or spiral jet mill, air classifier, single or multiple rotor air classifier, handstand air classifier, lab air classifier, ball grinding mill classifier, CJ series ultrafine jet mill, CJ traditional chinese medicine ultrafine jet mill, dry desulfurization equipment,professional equipment for deep processing of cracking carbon black,lithium cathode material crusher equipment,lithium cathode material crushing classification professional equipment and so on.

|

Type |

QLM03 |

QLM06 |

QLM10 |

QLM20 |

QLM40 |

|

Feeding particle size(mm) |

<3 |

<3 |

<3 |

<3 |

<3 |

|

Product particle size(d97:um) |

2~75 |

2~75 |

2~75 |

2~75 |

2~75 |

|

Production capacity(kg/h) |

5~80 |

10~200 |

20~400 |

50~1000 |

150~2500 |

|

Air consumption (m3/min) |

3 |

6 |

10 |

20 |

40 |

|

Air pressure |

0.7~0.85 |

0.7~0.85 |

0.7~0.85 |

0.7~0.85 |

0.7~0.85 |

|

Installed power |

30 |

47~64 |

68~98 |

145~164 |

250~298 |

Video

Weifang, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier