1 / 1

abs injection molding machine parts

| Model No. : | abs injection molding machine parts |

|---|---|

| Brand Name : | abs injection molding machine parts |

Product description

2.abs injection molding machine parts

3.QC inspection everywhere

4.Team work

1. kindly check the products we ever made,thanks! (*^__^*)

abs injection molding machine parts

abs injection molding machine parts

Mould standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard, etc |

Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ), etc |

Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13, etc |

Hardness of steel | 46~56HRC |

Material for Slider ,Lifter and all sub insert use | 1.2767 HRC |

Cavity | Single-cavity ,Multi-cavity |

A surface request: | EDM & High Polish |

Gate | Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

Maximum mould size | 1500*1500 mm |

Mould life time | 500000~+1,000,000 shots |

Quality | ISO9001-2001, ISO/TS16949:2004 certification |

Product material | PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

Lead time | 2~7 Weeks |

Package | Wooden/Plywood case for tool ,PE bags add export carton for parts |

Payment terms | T/T, L/C, Western Union, Paypal, etc |

Trade terms | FOB Shanghai, EXW ,CIF, etc |

Export country | Japan, Europe,USA,Mexico,Australia ,Middle-east ,Asia etc |

Value-added service | Polish,texture,painting,screen printing,turnkey project |

|

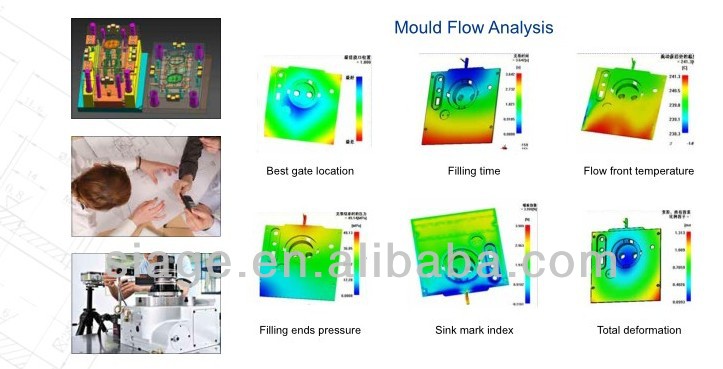

R&D alibility | My team can work on both product&mould design, software using here: UG/PRoE/Solidworks/Autocad,etc.Right now we already had 3 patents from my state.

|

|

Quality&Precision | 1. We utilize ISO9001:2008 & TS16949 standards in our operation

2. CNC tolerance: +/-0.005mm 3. WC tolerance:+/-0.003mm 4. EDM Mirror tolerance:+/-0.003mm 5. Precise Grinding Machine:+/-0.001mm

6.Main market:Japan,Europe,North America,you can expect the highest standard at most reasonable costs.

|

|

Professional Team | 1.my team have strong capability to support you from an idea or sample -design-production-surface treatment-assembly-packing-shipping,etc.

2.we have separate machining&mold making&injection&assembly workshops to meet your various requirements.

3.good knowledge to solve problems, be responsive.

4.Turnkey Project: We have one team with supervisory personnel to check the quality of product before and after producing line. |

|

After-sales Services |

Experienced engineers will provide all-round technical solutions to any problems occurred in customers mould operation.

Our belief: company's sustainable development means customer benefits,win-win situation-as we have been and will always deliver our products beyond customer expectation. |

Electronic: fingerprint head, Wireless receiver part, 3G/4G Modem Wireless Network Cards,USB housing, Mobile phone plastic part,remote control,key-press,handle.

Electronic: fingerprint head, Wireless receiver part, 3G/4G Modem Wireless Network Cards,USB housing, Mobile phone plastic part,remote control,key-press,handle.  Mechanical :Junction box,Motor support part,Pump plastic part,mower Household :Industrial number calculator part,Juice cup,safety helmet Medical :hearing aids,Hollow fiber Dialyzer,Blood-Pressure meter,Stapler Sport :Golf plastic part Office: Secret code case part,Printer,duplicator,Atom seal

Mechanical :Junction box,Motor support part,Pump plastic part,mower Household :Industrial number calculator part,Juice cup,safety helmet Medical :hearing aids,Hollow fiber Dialyzer,Blood-Pressure meter,Stapler Sport :Golf plastic part Office: Secret code case part,Printer,duplicator,Atom seal  QC ISO9001:2008 Certification

QC ISO9001:2008 Certification  QC (inspection everywhere ): - Firstly, check the raw material before massive production; - During production, technicians self-check and Engineer spot check to assure the good quality. - QC inspect after products finished - Before package, we will choose the best way to avoid damages during transportation. - Salesmen who were trained the technical know-how spot check before shipping. Packing&Shipping details:

QC (inspection everywhere ): - Firstly, check the raw material before massive production; - During production, technicians self-check and Engineer spot check to assure the good quality. - QC inspect after products finished - Before package, we will choose the best way to avoid damages during transportation. - Salesmen who were trained the technical know-how spot check before shipping. Packing&Shipping details:1. Pearl cotton or bubble package;

2. PE packing film;

3. Paper carton.

4.wood or moulded foam packing. If no special requirements,we will use standard export packages,thanks!

Right now we're working with over 30 countries,below are some pics taken during their visiting,thanks!

Right now we're working with over 30 countries,below are some pics taken during their visiting,thanks!

Tele: 86-21-57677097 Mob:86-18701728067 Skype:spm.cora Advantages of Siage Mould

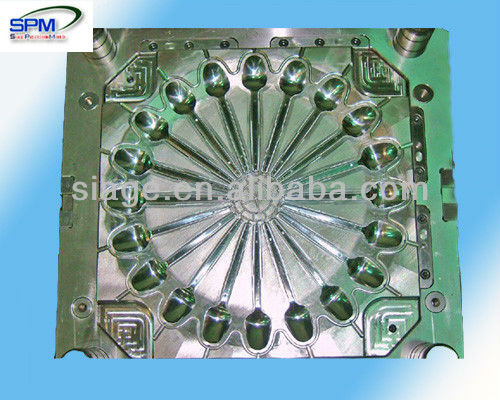

Tele: 86-21-57677097 Mob:86-18701728067 Skype:spm.cora Advantages of Siage Mould Shanghai Siage Precision Mould can make molds according to DME HASCO standard. we completely can reach the customer’s requirement because of the excellent and experienced design capability and software(UG, ProE, Solidworks,Catia,et.) complete processing equipment, strict quality control system. Injection Plastic Mold Maker Injection mold is one of our main businesses, Siage Mould specializes in all kinds of injection molds. Our plastic injection molding can from most plastics including PP / ABS / PC /PA / PBT / POM and so on.

Injection molding is an extremely versatile process for producing a wide range of simple or complex plastic parts with a good finish, Almost any 2D or 3D shape can be achieved, all plastic products can be produced through molds.

We can make mold for customer’s low-cost, high-quality production. Siage Mould provides service to the entire project development, including the design, mould manufacturer, plastic parts production and after sales service.

Send your inquiry to this supplier