1 / 6

AAC Autoclaved Aerated Concrete Blocks Brick Cutting Machine

| Model No. : | from 5000CBM/year to 200000CBM/year |

|---|---|

| Brand Name : | Huatong |

Product description

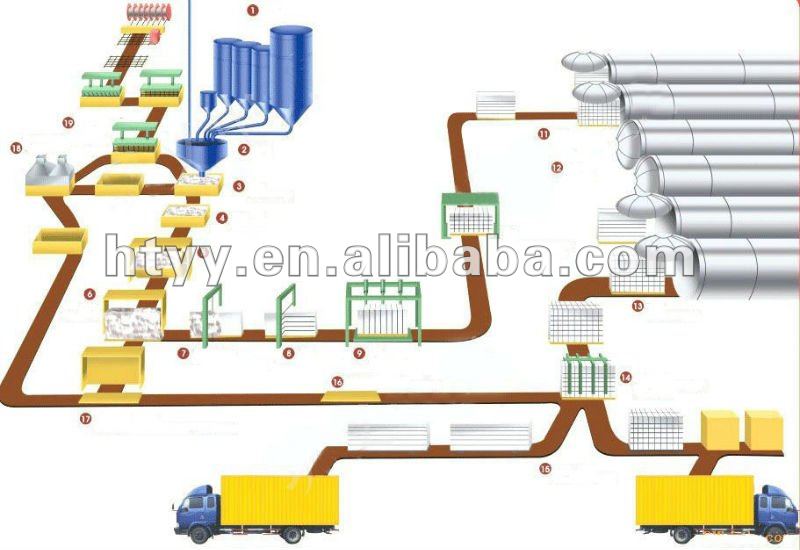

Specification There are 5 steps to make AAC Block: First, preparing raw material; Second, mixing the measured raw material to make slurry and pouring; Third, pre-ageing and cutting the green block body; Fourth, grouping the cut block and autoclaving; Fifth, packing the autoclaved block and transporting out of plant. Advantages of AAC blocks New Design Coal Ash AAC Block Making Machine Cutting Plant 1, Light Weight.The weight of the aerated concrete block generally is 500-700kg/cube meters whick is the same with 1/3-1/4 of clay brick or 1/4 of nomal concrete brick. 2, Thermal Insulation.The block’s thermal coefficient is 0.11-0.16Kcal/m.h.°C. It is 1/4-15 of the clay brick or limesand brick.It is 1/6 of normal concrete brick.. 3, Seismic Resistance.According to the analysis, has the good overall performance and small Inertial force, so it has seismic resistance. 4, Easy Machining.Aerated concrete brick has very good processing performance . It can be saw, plane, nails, drill. This brings great convenience and flexibility. 5, High Temperature Resistant.When the temperature at 600 degrees, the compression strength at close to the compressive strength of normal temperature

Specification There are 5 steps to make AAC Block: First, preparing raw material; Second, mixing the measured raw material to make slurry and pouring; Third, pre-ageing and cutting the green block body; Fourth, grouping the cut block and autoclaving; Fifth, packing the autoclaved block and transporting out of plant. Advantages of AAC blocks New Design Coal Ash AAC Block Making Machine Cutting Plant 1, Light Weight.The weight of the aerated concrete block generally is 500-700kg/cube meters whick is the same with 1/3-1/4 of clay brick or 1/4 of nomal concrete brick. 2, Thermal Insulation.The block’s thermal coefficient is 0.11-0.16Kcal/m.h.°C. It is 1/4-15 of the clay brick or limesand brick.It is 1/6 of normal concrete brick.. 3, Seismic Resistance.According to the analysis, has the good overall performance and small Inertial force, so it has seismic resistance. 4, Easy Machining.Aerated concrete brick has very good processing performance . It can be saw, plane, nails, drill. This brings great convenience and flexibility. 5, High Temperature Resistant.When the temperature at 600 degrees, the compression strength at close to the compressive strength of normal temperature Equipment lists (The equipment will be divided into two parts: specialized equipment and universal equipment): |

| Specialized equipment includes: 1. Cutting equipment: tilting crane, cutter. 2. Proportioning equipment: electronic measuring scale, slurry beating machine, slurry storage tank, slurry mixer. 3. Pouring and autoclave equipment: aluminum powder mixer. Pouring mixer, mould, side plate, autoclave truck, carrier car. 4. Conveying equipment: semi-product crane, end product crane. Universal equipment includes: 1. Pressure vessel equipment: boiler, autoclave. 2. Crushing equipment: ball miller, crusher. 3. Transportation equipment: crane, lifting machine, feeder, belt conveyor, slurry pump, screw conveyor. 4. Enviornment protect equipment: dust remover.

|

Preparation work New Design Coal Ash AAC Block Making Machine Cutting Plant 1. Land of 10000 m2 is required 2. Total Plant equipment area ( construction area ) : 2000 M2 - 3000 M2 3. Power connection needed – 500 KVA, Ideal manpower requirement is 40 nos. (High Skilled – 10, skilled -10 and unskilled 20) 4. Skill division 40 workers = Main plant 2 nos of 10 hour shifts, 15 people each + Boiler & Autoclave section 3 people in 3 shifts of 8 hours 5. Water requirement approximately 225 Tons per day, Fly Ash requirement approximately 225 Tons per day 6. The above power and plant calculations are based on Fly ash based AAC without Lime Crushing Unit and Ball mill for sand. If the process require, we may add them at a later stage. 7. AAC Blocks of varies sizes will be manufactured according to the market requirement, though mainly stipulated sizes as per the BIS standards.

Preparation work New Design Coal Ash AAC Block Making Machine Cutting Plant 1. Land of 10000 m2 is required 2. Total Plant equipment area ( construction area ) : 2000 M2 - 3000 M2 3. Power connection needed – 500 KVA, Ideal manpower requirement is 40 nos. (High Skilled – 10, skilled -10 and unskilled 20) 4. Skill division 40 workers = Main plant 2 nos of 10 hour shifts, 15 people each + Boiler & Autoclave section 3 people in 3 shifts of 8 hours 5. Water requirement approximately 225 Tons per day, Fly Ash requirement approximately 225 Tons per day 6. The above power and plant calculations are based on Fly ash based AAC without Lime Crushing Unit and Ball mill for sand. If the process require, we may add them at a later stage. 7. AAC Blocks of varies sizes will be manufactured according to the market requirement, though mainly stipulated sizes as per the BIS standards.

Raw materials New Design Coal Ash AAC Block Making Machine Cutting Plant Fly-Ash: The Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Lime: Active powered lime is a requirement for giving the real aeration to the product. In phase 1 we can aim to buy the active lime directly. OPC. This Project aims to utilize OPC cement as main binder material. It will give faster strength to the bricks, besides giving improved consistent quality. It also ensures a better cost effectiveness for the same. Gypsum: This too is an industrial waste. This is available as an industrial byproduct of Fertilizer Plant. Gypsum is responsible to give long term strength to the Blocks. Aluminum Power: Finely ground Aluminum power is used in very limited quantity ( less than 0.5%), so that it reacts with active lime, and silica in base material to make the aeration.

Raw materials New Design Coal Ash AAC Block Making Machine Cutting Plant Fly-Ash: The Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Lime: Active powered lime is a requirement for giving the real aeration to the product. In phase 1 we can aim to buy the active lime directly. OPC. This Project aims to utilize OPC cement as main binder material. It will give faster strength to the bricks, besides giving improved consistent quality. It also ensures a better cost effectiveness for the same. Gypsum: This too is an industrial waste. This is available as an industrial byproduct of Fertilizer Plant. Gypsum is responsible to give long term strength to the Blocks. Aluminum Power: Finely ground Aluminum power is used in very limited quantity ( less than 0.5%), so that it reacts with active lime, and silica in base material to make the aeration.

Cement lime fly ash style aerated block raw material proportion

Cement lime fly ash style aerated block raw material proportion Name | unit | Cement lime fly ash |

fly ash | % | 65-70 |

Cement | % | 6-15 |

Lime | % | 18-25 |

Gypsum | % | 3-5 |

Aluminum powder paste(600kg/m3) | 1/10000 | 8 |

Water & material rate |

| 0.60-0.65 |

Casting system | OC | 36-40 |

Aluminum mixing time | S | 30-40 |

Name | Unit | Cement Lime Sand |

Sand | % | 55-65 |

Cement | % | 10-20 |

Lime | % | 20-30 |

Gypsum | % | 2-3 |

Aluminum powder paste(600kg/m3) | 1/10000 | 8 |

Water & material rate |

| 0.65-0.75 |

Casting system | OC | 35-38 |

Aluminum mixing time | S | 30-40 |

Length(mm) | Height(mm) | Width(mm) |

600 | 150 200 250 300 | 100 125 150 200 250 |

Company Information

Company Information  Huatong Hydraulic Machinery Co.,Ltd is belongs to Huatong group, which is founded in 1986, one of the leading supplier of Concrete Block Machine, AAC Block production plant, Cement concrete mixing station in China. Huatong owns core technologies of concrete block machine and fly ash light weight AAC Block Machine. We manufacture QT10-15, QT8-15, QT7-15, QT5-15 automatic block making Machine, QT7-15, QT5-15, QT4-15 semi automatic block making machine. Our AAC concrete block making Machine annually production are 50,000 cbm, 100,000 cbm, 150,000 cbm and 200,000 cbm. Our block machines can produces various kinds of blocks / bricks by changing molds. We are the top brand of block making machine in china, AAA Enterprise of Qualityand Service, and certificated by ISO9001. All the main parts of the production lines are made by our own factories, that's why we can give you most competitive price. Sincerely welcome you to visist our factories!

Huatong Hydraulic Machinery Co.,Ltd is belongs to Huatong group, which is founded in 1986, one of the leading supplier of Concrete Block Machine, AAC Block production plant, Cement concrete mixing station in China. Huatong owns core technologies of concrete block machine and fly ash light weight AAC Block Machine. We manufacture QT10-15, QT8-15, QT7-15, QT5-15 automatic block making Machine, QT7-15, QT5-15, QT4-15 semi automatic block making machine. Our AAC concrete block making Machine annually production are 50,000 cbm, 100,000 cbm, 150,000 cbm and 200,000 cbm. Our block machines can produces various kinds of blocks / bricks by changing molds. We are the top brand of block making machine in china, AAA Enterprise of Qualityand Service, and certificated by ISO9001. All the main parts of the production lines are made by our own factories, that's why we can give you most competitive price. Sincerely welcome you to visist our factories!  Our Services Our full life service! We have big technical team of more than 50 staffs, offer full life service of our products, to guarantee our customers using our easy working machine with fruitful profit! 1. We will give you scientific advice and help you to select proper machine before placing order. 2. After shipment made, We will send our engineer to your area helping you to make exact and economical design of the confirmed project. Before machine reaching your area, more engineers will go to your factory preparing installation and debugging. 3. Our engineers will finish all work until the machine start nice working. We will train your own engineers the machine repair and maintenance technology. 4. At any time, if the machine could not work well, our engineer will help you to solve all problems.If necessary, we will send our engineer to your factory to repair the machine or replace the parts. 5. One time buying, full life service and co-operation. Our work is to make our customer free by using our machinery! It's not a word, it's based on our hard work and high reputation! Contact Info.

Our Services Our full life service! We have big technical team of more than 50 staffs, offer full life service of our products, to guarantee our customers using our easy working machine with fruitful profit! 1. We will give you scientific advice and help you to select proper machine before placing order. 2. After shipment made, We will send our engineer to your area helping you to make exact and economical design of the confirmed project. Before machine reaching your area, more engineers will go to your factory preparing installation and debugging. 3. Our engineers will finish all work until the machine start nice working. We will train your own engineers the machine repair and maintenance technology. 4. At any time, if the machine could not work well, our engineer will help you to solve all problems.If necessary, we will send our engineer to your factory to repair the machine or replace the parts. 5. One time buying, full life service and co-operation. Our work is to make our customer free by using our machinery! It's not a word, it's based on our hard work and high reputation! Contact Info.

Send your inquiry to this supplier