Video

1 / 5

65 QV-SP Non-edge angle wear abrasive Slurry Pumps

$1600.00

≥1 Set/Sets

| Model No. : | 65QV-SP |

|---|---|

| Brand Name : | NaiPu |

| Type : | Clay Wet Sand |

Shijiazhuang, Hebei, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

65 QV-SP Non-edge angle abrasive Slurry Pumps

Vertical sump pumps/metal liner sump pumps/centrifugal slurry pumps/delivering abrasive slurry pumps/abrasion-resistant metal sump pumps/non-edge angle abrasive slurry sump pumps.

Features

1.Submerged in water and sitting on the bottom of the sump,the SP series vertical sump pump is commly used to convey high-viscosity slurries with highly abrasive,coarse particles.

2.A key feature of this sump pump is the one-piece pump housing.Wet-end parts are replaceable and made of high-chrome for maximum corrosion resistance.Rubber and polyurethane are selected to make the pump liner and impeller.The sump pump can be used for different pumping applications.

3.Various types of impellers are designed to handle different pumping tasks.

4.Vertical cantilever design elimates the need of shaft seal or sealing water.

5.Parts submerged in the slurry can be made of metal or rubber.

Advantages

1.The physical layout of the submersible sump pump simplifies maintenance operations.

2.The sump pump body is bolted to the support plate.On top of the support plate sits the bearing assembly.Closer to the pump end is a double-row tapered roller bearing.Connected to the drive end is a single-row cylindrical roller bearing.

3.Installed on the bearing assembly is a motor support frame,or motor mounting base,where the motor is mounted,Flexible coupling or drive belt connects the motor shaft and the pump shaft.

4.Without any shaft seal or sealing water,the centrifugal sump pump can function properly even when there is insufficient slurry getting to the suction side.

5.A screen filter is set at the suction side to separate large particles out of the slurry.

Hydraulic Modeling

The open impeller design has vanes on both sides to balance the centrifugal forces thereby ensuring stable operation.Wide flow passage allows large particles and high-viscosity slurries to pass.

Trasmission

Grease-lubricated bearing assembly.Double-row tappered roller bearing is closer to the pump shaft end while single-row cylindrical roller bearing is closer to the drive end.

Installation Types

DC: The motor mounting base is set above the bearing assembly,so it is easy to replace or repair the motor parts.

BD:A V-Belt is used to connect the motor shaft and the pump shaft.The motor support frame is installed above the bearing assembly,allowing easy replacement of grooved wheels.The purpose of swapping grooved wheels is to change the rotary speed of the pump shaft in order to suit varing pumping applications or conform to the worn-down sump pump.

Applications

The sump pump is widely used in feeding slurries to the hydrocyclone or pressure filter in the mining industry,froth flotation,minerals recycling,mine dewatering,flue gas desulphurization in power plant,coal washing,metallurgy,pulp and paper manufacture and chemical engineering.

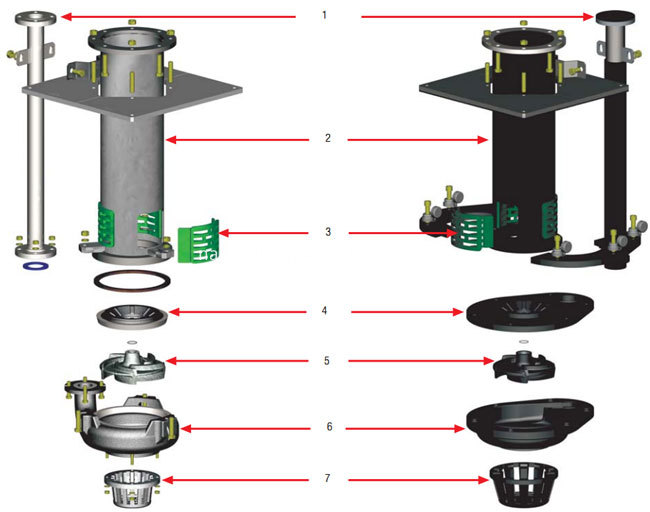

NP-SP(R) Sump Pump Showing Component

Vertical sump pumps/metal liner sump pumps/centrifugal slurry pumps/delivering abrasive slurry pumps/abrasion-resistant metal sump pumps/non-edge angle abrasive slurry sump pumps.

Product Overview:

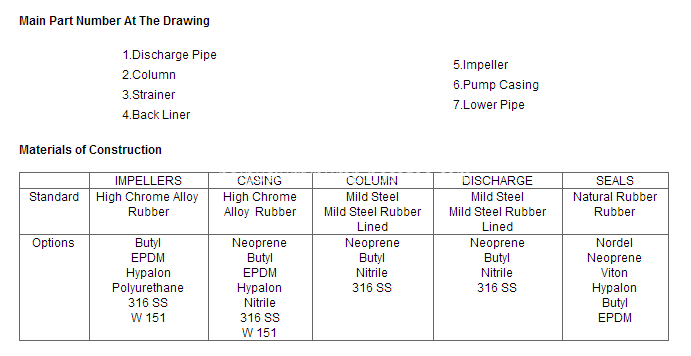

Workshop Photos:

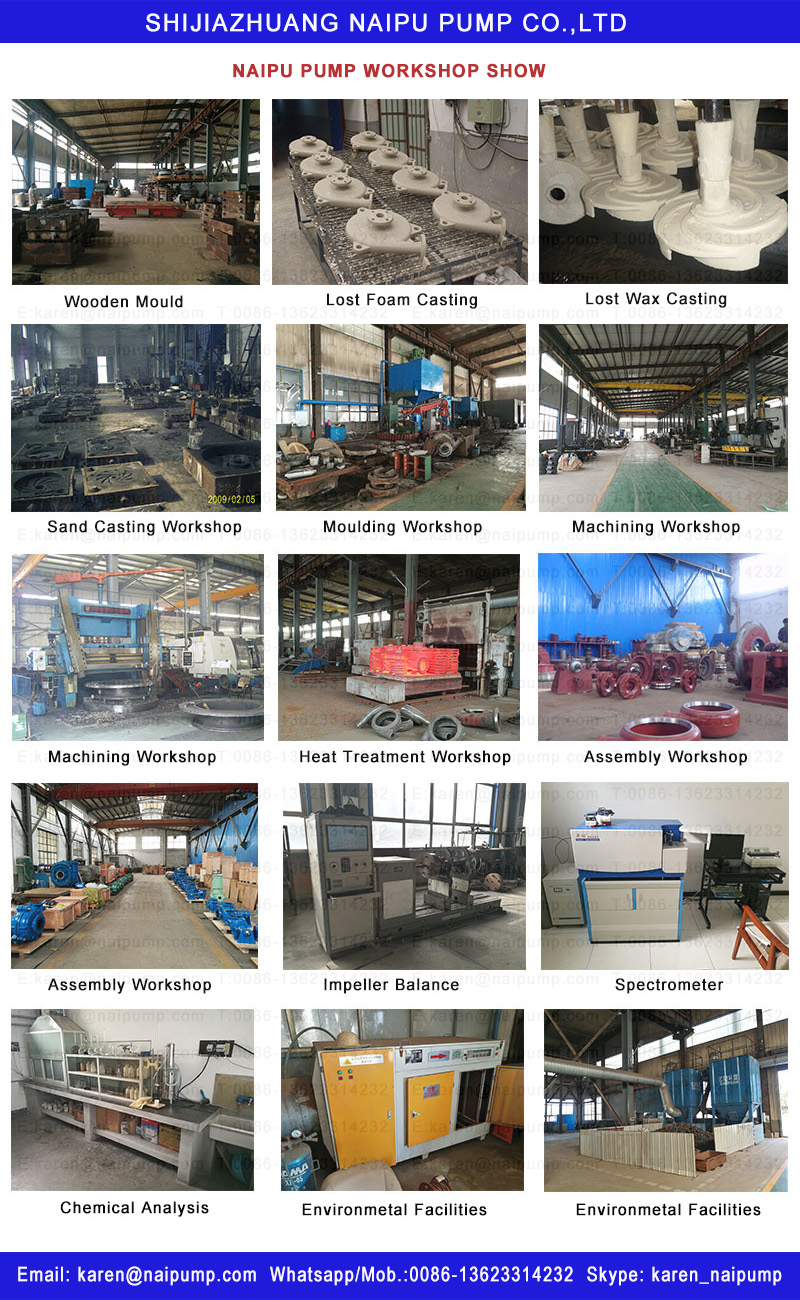

Quality Control System

Contact US:

Shijiazhuang Naipu Pump Co.,Ltd

Add: No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industry Development Zone Hebei,China 050091.

Contact Person: Karen Tan

Skype:karen_naipump

If you have any query,please don't hesitate to contact me.

Video

Shijiazhuang, Hebei, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier