1 / 6

5R4125, ISO9001 Certificated Carbon Black Powder Grinding Machine in India

Get Latest Price

Send Inquiry

| Model No. : | 5R4125 |

|---|---|

| Brand Name : | Gui Kuang |

Guilin Mining Machinery Co., Ltd.

You might also like

Product description

5R4125, ISO9001 Certificated Carbon Black Powder Grinding Machine in India

Main Technical Data:

Main Technical Data:

Raymond Mill is the ideal solution for pulverizing almost any non-metallic minerals with Moh’s hardness below 7 and moisture content below 6%, such as marble, calcite, limestone, feldspar, fluorite, gypsum, talc , barite, dolomite, granite, kaolin, bentonite, bauxite, phosphorite, figuline, black lead, clay etc. The fitness of the final product can be adjusted as required in the range of 100-325 meshes. After years of practice and innovation, Raymond mills provided by Guikuang are getting perfect day by day. Our product lists are range from 2R to 6R, including 2R2613, 3R3220, 4R3216, 4R3216B, 5R4125, 5R4128, GK1720. The mill feeder, roller mill size, classifier, fan, cyclone, dust collector and other system components are selected to meet the requirements and characteristics of the material being processed.

Raymond Mill is the ideal solution for pulverizing almost any non-metallic minerals with Moh’s hardness below 7 and moisture content below 6%, such as marble, calcite, limestone, feldspar, fluorite, gypsum, talc , barite, dolomite, granite, kaolin, bentonite, bauxite, phosphorite, figuline, black lead, clay etc. The fitness of the final product can be adjusted as required in the range of 100-325 meshes. After years of practice and innovation, Raymond mills provided by Guikuang are getting perfect day by day. Our product lists are range from 2R to 6R, including 2R2613, 3R3220, 4R3216, 4R3216B, 5R4125, 5R4128, GK1720. The mill feeder, roller mill size, classifier, fan, cyclone, dust collector and other system components are selected to meet the requirements and characteristics of the material being processed.  The running Principle:

The running Principle: Materials are broken by crusher into pieces less than 20 mm which are carried by bucket elevator up to the storage hopper .Then the electromagnetic vibrating feeder transports the crushed material at a given rate to the gring chamber. Six grinding roller units hang on the runing brackets which rotating around the roller shaft. Under the action of centrifugal force, grinding roller moving outward and press against the grinding ring. the raw materials are introduced into the grinding zone by the force of plough blade. After grinding, the powder is blown to the turbine classifying machine, the coarse particals are resisted and fall back into the grinding chamber for regrinding, while the fineness which meets the specifications, with the wind enter the cyclone collector and collected. After purified, the air through a pipe channel whcih lay upper end of the cyclone collector, flow into the blower. The airflow path is the circulation, the only positive pressure part is between the blower and the grinding chamber, the others, the air flow under negative pressure. the workshop is dustless. The air volume increased because the material contain some water which in the grinding process is heated and evaporated into gas; And the pipe flange junction, the material feeding inlet etc. leaks air into the pipe channel, which increase air volume too. So, between the air blower and the grinding chamber, there is a small whirlwind collector which drains the extra air after further purified. 5R4125 Improved Grinding Mill is improved from 5R4124.The output is increased by 20% more than that of 5R4124.

Materials are broken by crusher into pieces less than 20 mm which are carried by bucket elevator up to the storage hopper .Then the electromagnetic vibrating feeder transports the crushed material at a given rate to the gring chamber. Six grinding roller units hang on the runing brackets which rotating around the roller shaft. Under the action of centrifugal force, grinding roller moving outward and press against the grinding ring. the raw materials are introduced into the grinding zone by the force of plough blade. After grinding, the powder is blown to the turbine classifying machine, the coarse particals are resisted and fall back into the grinding chamber for regrinding, while the fineness which meets the specifications, with the wind enter the cyclone collector and collected. After purified, the air through a pipe channel whcih lay upper end of the cyclone collector, flow into the blower. The airflow path is the circulation, the only positive pressure part is between the blower and the grinding chamber, the others, the air flow under negative pressure. the workshop is dustless. The air volume increased because the material contain some water which in the grinding process is heated and evaporated into gas; And the pipe flange junction, the material feeding inlet etc. leaks air into the pipe channel, which increase air volume too. So, between the air blower and the grinding chamber, there is a small whirlwind collector which drains the extra air after further purified. 5R4125 Improved Grinding Mill is improved from 5R4124.The output is increased by 20% more than that of 5R4124.  Features: 1, Reducer Adopts New-type Deceleration Device: The speed of main engine can be adjusted flexibly to meet the hardness of material. 2,Strong ability of shoveling material: Adopting super large shovel blade to shovel as much as possible to the grinding area between the roll and ring. 3, Expanding Grinding Area: The grinding area is expanded by heightening host base , roll and ring. 4, High Classification Accuracy: Super large classification turbine brings a higher passing ratio and stronger airflow. In addition, the labyrinth seal between the edge surface of blade turbine and powder outlet decreases the short circuit powder, which results in a high classification precision. 5, Dual Cyclone Collector: The collecting efficiency is up to 80% and 10% higher than single cyclone collector. 6 Large Transmission Capability: Blower adopts high pressure centrifugal fan, which results in high air volume and pressure and improving the pneumatic conveying ability 7,The rest powder is collected by sack ,so the workshop will be clean.

Features: 1, Reducer Adopts New-type Deceleration Device: The speed of main engine can be adjusted flexibly to meet the hardness of material. 2,Strong ability of shoveling material: Adopting super large shovel blade to shovel as much as possible to the grinding area between the roll and ring. 3, Expanding Grinding Area: The grinding area is expanded by heightening host base , roll and ring. 4, High Classification Accuracy: Super large classification turbine brings a higher passing ratio and stronger airflow. In addition, the labyrinth seal between the edge surface of blade turbine and powder outlet decreases the short circuit powder, which results in a high classification precision. 5, Dual Cyclone Collector: The collecting efficiency is up to 80% and 10% higher than single cyclone collector. 6 Large Transmission Capability: Blower adopts high pressure centrifugal fan, which results in high air volume and pressure and improving the pneumatic conveying ability 7,The rest powder is collected by sack ,so the workshop will be clean.

Xinjiang 5R4128 installation on site  Xinjiang bentonite, 60000 tons of production lines

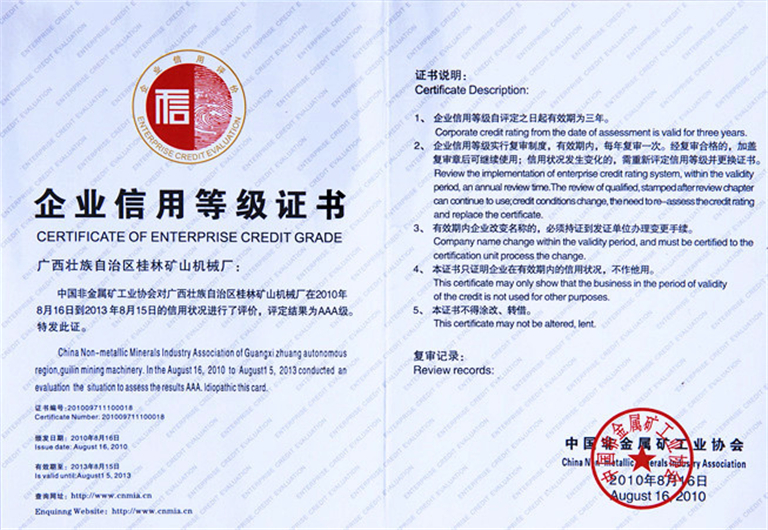

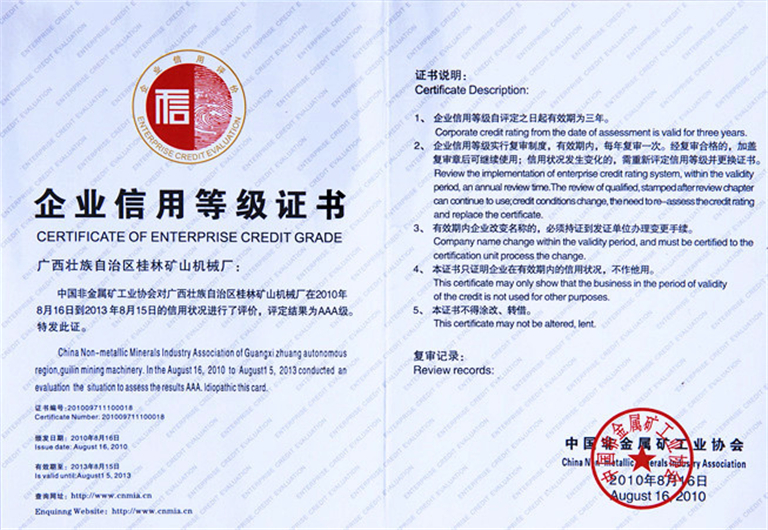

Xinjiang bentonite, 60000 tons of production lines  Qualification and Certificate:

Qualification and Certificate:

Phone:+86-773-6812095/+86-773-6811016

Phone:+86-773-6812095/+86-773-6811016

Fax: +86-773-6812096 Skype/whatsapp: co2_erich Telephone: +86-1507-8944-045

Address:NO.1 Guikuang Road Lingchuan County,Guilin City,Guangxi,China

Web: www.guikuang.com

Main Technical Data:

Main Technical Data: Max Feeding Size | Product Fineness | Capacity | Central Shaft Speed | Inner Diameter of Ring | Grinding Roll Size (OD*Height) | Total Weight | Total Power |

30 mm | 80~400 mesh | 2000~14000 kg/h | 105 r/min | φ1270 mm | Φ410*280mm | 29.6 t | 220.5KW |

Raymond Mill is the ideal solution for pulverizing almost any non-metallic minerals with Moh’s hardness below 7 and moisture content below 6%, such as marble, calcite, limestone, feldspar, fluorite, gypsum, talc , barite, dolomite, granite, kaolin, bentonite, bauxite, phosphorite, figuline, black lead, clay etc. The fitness of the final product can be adjusted as required in the range of 100-325 meshes. After years of practice and innovation, Raymond mills provided by Guikuang are getting perfect day by day. Our product lists are range from 2R to 6R, including 2R2613, 3R3220, 4R3216, 4R3216B, 5R4125, 5R4128, GK1720. The mill feeder, roller mill size, classifier, fan, cyclone, dust collector and other system components are selected to meet the requirements and characteristics of the material being processed.

Raymond Mill is the ideal solution for pulverizing almost any non-metallic minerals with Moh’s hardness below 7 and moisture content below 6%, such as marble, calcite, limestone, feldspar, fluorite, gypsum, talc , barite, dolomite, granite, kaolin, bentonite, bauxite, phosphorite, figuline, black lead, clay etc. The fitness of the final product can be adjusted as required in the range of 100-325 meshes. After years of practice and innovation, Raymond mills provided by Guikuang are getting perfect day by day. Our product lists are range from 2R to 6R, including 2R2613, 3R3220, 4R3216, 4R3216B, 5R4125, 5R4128, GK1720. The mill feeder, roller mill size, classifier, fan, cyclone, dust collector and other system components are selected to meet the requirements and characteristics of the material being processed.  The running Principle:

The running Principle: Materials are broken by crusher into pieces less than 20 mm which are carried by bucket elevator up to the storage hopper .Then the electromagnetic vibrating feeder transports the crushed material at a given rate to the gring chamber. Six grinding roller units hang on the runing brackets which rotating around the roller shaft. Under the action of centrifugal force, grinding roller moving outward and press against the grinding ring. the raw materials are introduced into the grinding zone by the force of plough blade. After grinding, the powder is blown to the turbine classifying machine, the coarse particals are resisted and fall back into the grinding chamber for regrinding, while the fineness which meets the specifications, with the wind enter the cyclone collector and collected. After purified, the air through a pipe channel whcih lay upper end of the cyclone collector, flow into the blower. The airflow path is the circulation, the only positive pressure part is between the blower and the grinding chamber, the others, the air flow under negative pressure. the workshop is dustless. The air volume increased because the material contain some water which in the grinding process is heated and evaporated into gas; And the pipe flange junction, the material feeding inlet etc. leaks air into the pipe channel, which increase air volume too. So, between the air blower and the grinding chamber, there is a small whirlwind collector which drains the extra air after further purified. 5R4125 Improved Grinding Mill is improved from 5R4124.The output is increased by 20% more than that of 5R4124.

Materials are broken by crusher into pieces less than 20 mm which are carried by bucket elevator up to the storage hopper .Then the electromagnetic vibrating feeder transports the crushed material at a given rate to the gring chamber. Six grinding roller units hang on the runing brackets which rotating around the roller shaft. Under the action of centrifugal force, grinding roller moving outward and press against the grinding ring. the raw materials are introduced into the grinding zone by the force of plough blade. After grinding, the powder is blown to the turbine classifying machine, the coarse particals are resisted and fall back into the grinding chamber for regrinding, while the fineness which meets the specifications, with the wind enter the cyclone collector and collected. After purified, the air through a pipe channel whcih lay upper end of the cyclone collector, flow into the blower. The airflow path is the circulation, the only positive pressure part is between the blower and the grinding chamber, the others, the air flow under negative pressure. the workshop is dustless. The air volume increased because the material contain some water which in the grinding process is heated and evaporated into gas; And the pipe flange junction, the material feeding inlet etc. leaks air into the pipe channel, which increase air volume too. So, between the air blower and the grinding chamber, there is a small whirlwind collector which drains the extra air after further purified. 5R4125 Improved Grinding Mill is improved from 5R4124.The output is increased by 20% more than that of 5R4124.  Features: 1, Reducer Adopts New-type Deceleration Device: The speed of main engine can be adjusted flexibly to meet the hardness of material. 2,Strong ability of shoveling material: Adopting super large shovel blade to shovel as much as possible to the grinding area between the roll and ring. 3, Expanding Grinding Area: The grinding area is expanded by heightening host base , roll and ring. 4, High Classification Accuracy: Super large classification turbine brings a higher passing ratio and stronger airflow. In addition, the labyrinth seal between the edge surface of blade turbine and powder outlet decreases the short circuit powder, which results in a high classification precision. 5, Dual Cyclone Collector: The collecting efficiency is up to 80% and 10% higher than single cyclone collector. 6 Large Transmission Capability: Blower adopts high pressure centrifugal fan, which results in high air volume and pressure and improving the pneumatic conveying ability 7,The rest powder is collected by sack ,so the workshop will be clean.

Features: 1, Reducer Adopts New-type Deceleration Device: The speed of main engine can be adjusted flexibly to meet the hardness of material. 2,Strong ability of shoveling material: Adopting super large shovel blade to shovel as much as possible to the grinding area between the roll and ring. 3, Expanding Grinding Area: The grinding area is expanded by heightening host base , roll and ring. 4, High Classification Accuracy: Super large classification turbine brings a higher passing ratio and stronger airflow. In addition, the labyrinth seal between the edge surface of blade turbine and powder outlet decreases the short circuit powder, which results in a high classification precision. 5, Dual Cyclone Collector: The collecting efficiency is up to 80% and 10% higher than single cyclone collector. 6 Large Transmission Capability: Blower adopts high pressure centrifugal fan, which results in high air volume and pressure and improving the pneumatic conveying ability 7,The rest powder is collected by sack ,so the workshop will be clean.

Xinjiang bentonite, 60000 tons of production lines

Xinjiang bentonite, 60000 tons of production lines  Qualification and Certificate:

Qualification and Certificate:

Phone:+86-773-6812095/+86-773-6811016

Phone:+86-773-6812095/+86-773-6811016 Fax: +86-773-6812096 Skype/whatsapp: co2_erich Telephone: +86-1507-8944-045

Address:NO.1 Guikuang Road Lingchuan County,Guilin City,Guangxi,China

Web: www.guikuang.com

Send your inquiry to this supplier

Send Inquiry