1 / 5

5 Tons Waste Tire Recycling To Oil Machine

| Model No. : | LJ-8 |

|---|---|

| Brand Name : | SIHAI |

| Certification : | ISO |

Product description

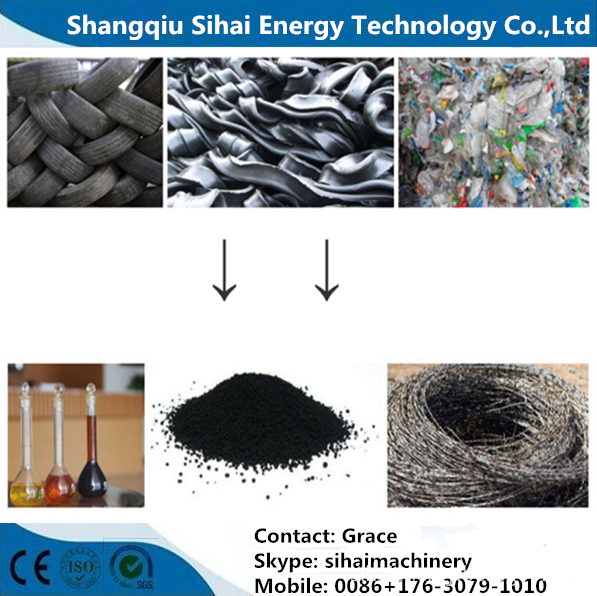

5 Tons Waste Tire Recycling To Oil Machine

Technical parameters of the 5 Tons Waste Tire Recycling To Oil Machine:

|

Model |

Raw material |

Structure form |

Cooling system |

|

LJ-8 |

Waste tire, plastic, rubber |

Horizontal |

Water cooling |

|

Heating method |

Oil output rate |

Power |

Installation |

|

Directly |

45% |

15.5KW |

Foundation |

|

24 hours processing capacity |

24 hours oil output |

Work pressure |

Host speed |

|

6-8 tons raw materials |

2.5-3.2 tons fuel oil |

Atmospheric |

0.4r\min |

|

Transport |

Reactor size |

Working form |

Weight of reactor |

|

External gear drive |

2200*6000mm |

Batch |

28 tons |

Main components of the 5 Tons Waste Tire Recycling To Oil Machine:

a. Host horizontal rotary pyrolysis processor.

b. Feeding system

c. Pressure and temperature alarm system

d. Secondary catalytic tower

e. Automatic slag removal system

f. Central electronic control system

g. Tank cooling system

h. Gas heating system (exhaust gas treatment system)

i. Dust and dust removal system

Features of the 5 Tons Waste Tire Recycling To Oil Machine:

a. In the design of pyrolysis key device, completely overcome the local heat uneven, easy to break, low yield, short life and other unfavorable factors of the current vertical flat bottom pyrolysis plant.

b. With fast and practical feed and slag system.

c. Efficient gas heating system. In the process of refining, when the heated gas reaches 150 degrees Celsius, it will produce a lot of gas which can not be liquefied in normal temperature and pressure methane to butane.These gases are fully burned by specially designed gas nozzles, will produce a lot of energy which greatly saves energy.

d.Flue dust removal system has a desulfurization dust cather(qualified), equipped with two ways water impact cyclone dust removal chamber, which can ensure the discharge of flue outlet reach safe discharge standard.

Exporting experience of the 5 Tons Waste Tire Recycling To Oil Machine:

|

America: |

Brazil, Canada, Colombia, USA, |

|

Middle East: |

Dubai, Iran, Jordan, Saudi Arabia, Turkey |

|

Europe: |

Albania , Bosnia and Herzegovina |

|

Asia: |

Afghanistan, India, Malaysia, Pakistan, Philippines, South Korea, Vietnam, Myanmar,Thailand, Uzbekistan |

|

Africa: |

Ghana, Mozambique, Zambia |

Send your inquiry to this supplier