1 / 6

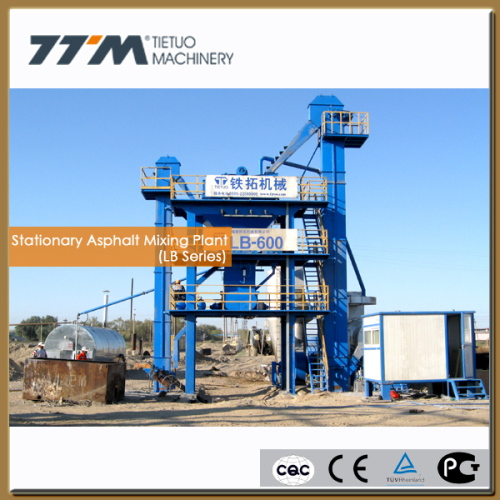

48t/h fixed asphalt mixing plant, concrete mixing plants

Get Latest Price

Send Inquiry

| Model No. : | LB-600 |

|---|---|

| Brand Name : | TTM,TIETUO |

Fujian Tietuo Machinery Co.

You might also like

Product description

Company Information

Company Information  Fujian Tietuo Machinery CO., Ltd (TTM for short), it’s a leading enterprise devoting to the design, research, production sale and maintenance of the asphalt mixing and recycling plant. TTM Positive response to the country’s energy consumption and pollution reduction, all along attention the innovate and progress, persistence investment in the core area for recycling domanial, and unite establish” R&D center Of asphalt mixing plant” with the SHANGDONG JIAOTONG University. We also introduction of Taiwan technology found Quanzhou Workstation of RAP Technology research. (we can supply large range of stationary asphalt mixing plant, from 48 tons per to 320 tons per hour) Product Description ------- 48t/h fixed asphalt mixing plant, concrete mixing plants ------- 1).Type: LB-600

Fujian Tietuo Machinery CO., Ltd (TTM for short), it’s a leading enterprise devoting to the design, research, production sale and maintenance of the asphalt mixing and recycling plant. TTM Positive response to the country’s energy consumption and pollution reduction, all along attention the innovate and progress, persistence investment in the core area for recycling domanial, and unite establish” R&D center Of asphalt mixing plant” with the SHANGDONG JIAOTONG University. We also introduction of Taiwan technology found Quanzhou Workstation of RAP Technology research. (we can supply large range of stationary asphalt mixing plant, from 48 tons per to 320 tons per hour) Product Description ------- 48t/h fixed asphalt mixing plant, concrete mixing plants ------- 1).Type: LB-600 2).Production: 48t/h

3).Hot Agg Bin: 7 m3

4).Capacity: 600kg

--------Main feature-------

--- 48t/h fixed asphalt mixing plant concrete mixing plants

1). The feeding belt is designed with baffles, which makes material feeding system steady and smooth.

2). The optimized flights structure of drying drum makes the drying system more effective and stable

3). The hot elevator adopts the double Gall's chain for hoisting, which not only prolongs the service life of the hoisting machine but also improves the running stability

4). The linear-mode screen driven by imported vibrator improves the screening efficiency and reduces the failure rate of plant

5). Large capacity hot aggregate bin makes operation more convenient

6). Our unqiue designed paddles and the powerful mixer allow the mixing operation easier, effective and reliable

7). Dual-stage dust removal system and negative pressure dustproof design make our asphalt mixing plant ecofriendly and economical

8). The computer-controlled system, auto/manual switchable, and auto self-diagnosis program makes the operation easy and safe

9). Overall modular design makes the transportation and installation more convenient and fast

10). The RAP interface is reserved for upgrade hot RAP facilities Simplified configuration, low failure rate, and suitable for road maintenance and medium and small scaled construction projects.

LB Series(without finished storage silo) | |||||

Type | Production | Hot Agg Bin | Capacity | Finished Storage Bin | Weighing Accuracy |

LB-600 | 48 t/h | 7 m3 | 600 kg |

No

|

Aggregate:±0.5% Filler :±0.5% Bitumen :±0.25%

|

LB-800 | 64 t/h | 7 m3 | 800 kg | ||

LB-1000 | 80 t/h | 10 m3 | 1000 kg | ||

LB-1200 | 96 t/h | 10 m3 | 1200 kg | ||

LB-1500 | 120 t/h | 30 m3 | 1500 kg | ||

LB-2000 | 160 t/h | 50 m3 | 2000 kg | ||

LB-2500 | 200 t/h | 50 m3 | 2500 kg | ||

LB-3000 | 240 t/h | 50 m3 | 3000 kg | ||

LB-4000 | 320 t/h | 50 m3 | 4000 kg | ||

1. Total dust collection with 1st-level inertial collecting, 2ND-level bag house and dust collecting modules for various portions of facilities.

2. We establish environment protection concepts according to the European standards to achieve in dust emission, acid emission and noise control, etc.

3. The facilities are in green harmony with the environment wherever we go. After-Sales Service Fujian TTM have after staff over 80 persons now, unified manage and deployment by the specialized agencies-customer service center, and establish a detailed customer files. The electrical and mechanical after service engineer's technical level and skill were fully qualified for the installation, adjustment, commissioning, training and advice the user's operators, administrators and provide free technical advisory services etc. --------Service contents--------:

--Installation and commissioning and acceptance

1). Our company will offer the buyer assistance of the equipment installation, commission ;

2). Each unit after installation will have returning visit by specialized departments;

--Technical material, warranty and free service

1). We will offer the buyer free training for their operator and maintenance worker, and also provide free technical advice services;

2). And company will organize technology training courses regularly, and give free training the buyer's operator.

--Spare parts supply services in time

Our company offers the original, authentic, quality spare parts for the machine maintenance accessories. Production Flow

TTM Informations

TTM Informations

Send your inquiry to this supplier

Send Inquiry