1 / 2

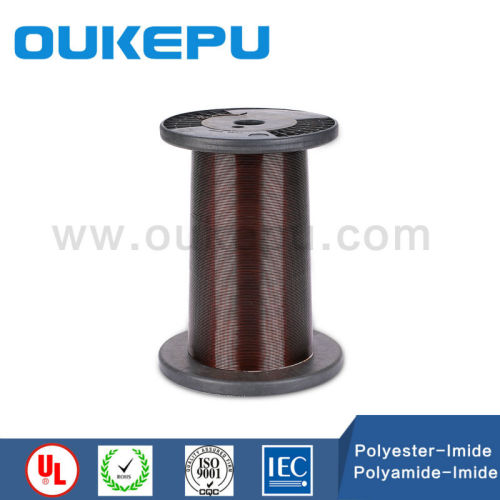

20years factory experience enamelled copper wire price,Enamelled copper magnet wire,buy enamelled wire

Get Latest Price

Send Inquiry

| Model No. : | enamelled wire |

|---|---|

| Brand Name : | OUKEPU |

Yueqing City Ouwei Electric Co., Ltd.

You might also like

Product description

20years factory experience enamelled copper wire price,Enamelled copper magnet wire,buy enamelled wire Product Description We can producing all the sizes in following :

Advantage 1.Ouwei factory Established in 2003, Located in zhejiang province,,China is a professional manufacturer of Enameled wire . 2.Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month . Application Specification Standards 1. IEC,ISO Specification 2. International/Customised Standard Applications ELECTRICAL MOTORS LIGHTING FIXTURES TRANSFORMERS COILS SWITCHGEAR SOLONOID VALVES AUTOMOBILES ELECTRICAL APPLIANCES INDUSTRIAL ELECTRONICS PUMPS&FANS

Advantage 1.Ouwei factory Established in 2003, Located in zhejiang province,,China is a professional manufacturer of Enameled wire . 2.Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month . Application Specification Standards 1. IEC,ISO Specification 2. International/Customised Standard Applications ELECTRICAL MOTORS LIGHTING FIXTURES TRANSFORMERS COILS SWITCHGEAR SOLONOID VALVES AUTOMOBILES ELECTRICAL APPLIANCES INDUSTRIAL ELECTRONICS PUMPS&FANS  WORKSHOP DETAILS

WORKSHOP DETAILS  More products

More products  Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

Packaging & Shipping Packing Details PT6 ,PT10 ,PT25 ,PT30,PT45,LPT60 ,Pt90 Pt190 & as per Customers Requirements Professional exprot packing for Round size

Packaging & Shipping Packing Details PT6 ,PT10 ,PT25 ,PT30,PT45,LPT60 ,Pt90 Pt190 & as per Customers Requirements Professional exprot packing for Round size Professional exprot packing for Rectangular size,Square size

Professional exprot packing for Rectangular size,Square size  Our Services

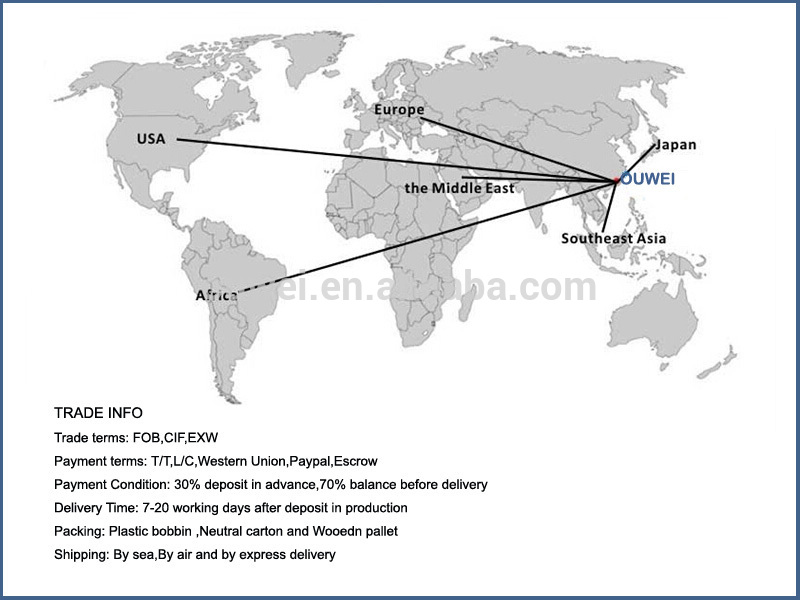

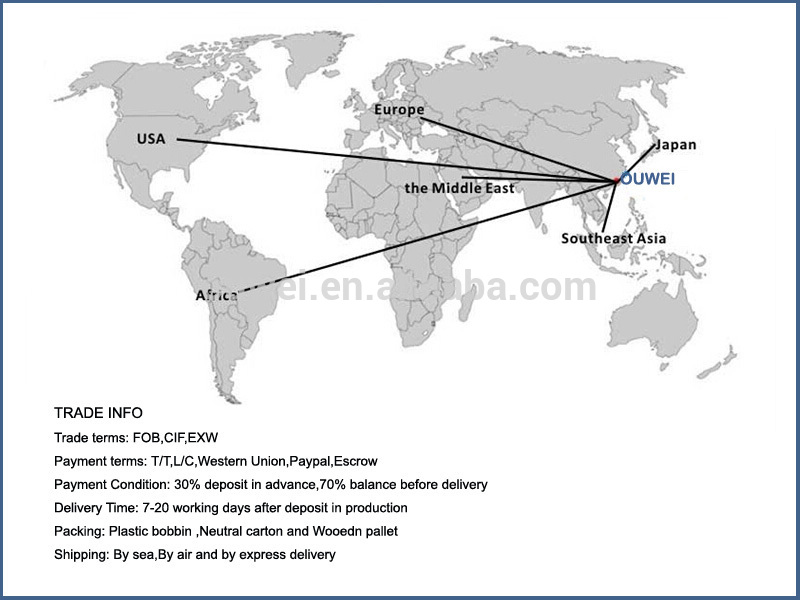

Our Services  8.Our products export many countries

8.Our products export many countries  FAQ Q: Are you a manufacturer or a trading company ? A: We are a professional manufacturer of enameled wire for rewinding in China . Q: how about your company’s annual production capacity? A: Our Company’s annual production are 1200ton/month. Q: How large the scale of your company? A: Our Company covers almost 2,700,000 square meters.and 76 sets included continuous extrusion. Q: How many kind of spools size ? A:PT4, PT10, PT15, PT25, PT35, PT60, PT90, wooden spools PT-500 and etc. Q : What is specifications of enameled wire your company can produce? A: 1.Enameled round wire: 0.10mm-6.00mm 2.Enameled rectangular wire: Side(a): 1mm-10mm, Side(b): 2mm-16mm 3.Kraft paper covered round wire: 1.5mm-5.0mm 4.Kraft paper covered ractangular wire: (a)1.0mm-5.6mm, (b) 2.00-16mm 5.Fiberglass covered round wire:1.00mm-8.00mm 6.Fiberglass covered rectangular wire:(a)1.00mm-5.60mm,(b)2.00mm-16.00mm Q : What’s the temperature-resist grade of your enameled wire? A: We produce the thermal class of enameled wire from class130 to class220

FAQ Q: Are you a manufacturer or a trading company ? A: We are a professional manufacturer of enameled wire for rewinding in China . Q: how about your company’s annual production capacity? A: Our Company’s annual production are 1200ton/month. Q: How large the scale of your company? A: Our Company covers almost 2,700,000 square meters.and 76 sets included continuous extrusion. Q: How many kind of spools size ? A:PT4, PT10, PT15, PT25, PT35, PT60, PT90, wooden spools PT-500 and etc. Q : What is specifications of enameled wire your company can produce? A: 1.Enameled round wire: 0.10mm-6.00mm 2.Enameled rectangular wire: Side(a): 1mm-10mm, Side(b): 2mm-16mm 3.Kraft paper covered round wire: 1.5mm-5.0mm 4.Kraft paper covered ractangular wire: (a)1.0mm-5.6mm, (b) 2.00-16mm 5.Fiberglass covered round wire:1.00mm-8.00mm 6.Fiberglass covered rectangular wire:(a)1.00mm-5.60mm,(b)2.00mm-16.00mm Q : What’s the temperature-resist grade of your enameled wire? A: We produce the thermal class of enameled wire from class130 to class220

| Enameled round aluminum wire

| Enameled flat aluminum wire

|

| Enameled round copper wire

| Enameled flat copper wire

|

| Non Woven Cloth/ Polyester Film covered wire

| Polyimide Film Wrapped wire

|

| Film Wrapped enameled wire

| NOMEX Paper covered wire

|

| Fiberglass Film Wrapped wire

| Kraft Paper Wrapped wire

|

Advantage 1.Ouwei factory Established in 2003, Located in zhejiang province,,China is a professional manufacturer of Enameled wire . 2.Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month . Application Specification Standards 1. IEC,ISO Specification 2. International/Customised Standard Applications ELECTRICAL MOTORS LIGHTING FIXTURES TRANSFORMERS COILS SWITCHGEAR SOLONOID VALVES AUTOMOBILES ELECTRICAL APPLIANCES INDUSTRIAL ELECTRONICS PUMPS&FANS

Advantage 1.Ouwei factory Established in 2003, Located in zhejiang province,,China is a professional manufacturer of Enameled wire . 2.Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month . Application Specification Standards 1. IEC,ISO Specification 2. International/Customised Standard Applications ELECTRICAL MOTORS LIGHTING FIXTURES TRANSFORMERS COILS SWITCHGEAR SOLONOID VALVES AUTOMOBILES ELECTRICAL APPLIANCES INDUSTRIAL ELECTRONICS PUMPS&FANS  WORKSHOP DETAILS

WORKSHOP DETAILS  More products

More products  Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc. | Code Number | Test Standard | GB/T23312-7-2009 | |

| Size | 2.0mm | Date | |

| Type Q(ZY/XY)L-240 polyesterimide coated with polyamideimide | |||

| Test Tens | Standard value | Test Result | |

| Size | Maximum | 2.112mm | 2.095mm |

| Conductor Diameter | 2.00mm | 2.012mm | |

| Tolerance Value | ±0.020mm | 0.012mm | |

| F Result | ≤0.020mm | 0.001mm | |

| Film Thickness | ≥0.075mm | 0.083mm | |

| 20°C Resistivity | 0.008698-0.009149Ω/m | 0.00903-Ω/m | |

| Elongation | ≥15% | 32.20% | |

| Adherence | Test Axis Around | Winding ID | OK |

| Flexibility | Sudden/Pull | ≥55R | 65R |

| Anti-Solvent | ≥1h | 2h | |

| Alt-Throngh | 320°C,2min | OK | |

| Hot Shock | 240°C,30min | OK | |

| Broken Down Voltage Will Room | ≥5.0KV | 11.3/9.7/12/11.5/kv | |

| Continuity | High Voltage Hole | / | / |

| Pin-Hole | ≤5pcs/6m | 1pcs | |

| Conculusion | OK | ||

Packaging & Shipping Packing Details PT6 ,PT10 ,PT25 ,PT30,PT45,LPT60 ,Pt90 Pt190 & as per Customers Requirements Professional exprot packing for Round size

Packaging & Shipping Packing Details PT6 ,PT10 ,PT25 ,PT30,PT45,LPT60 ,Pt90 Pt190 & as per Customers Requirements Professional exprot packing for Round size Professional exprot packing for Rectangular size,Square size

Professional exprot packing for Rectangular size,Square size  Our Services

Our Services  8.Our products export many countries

8.Our products export many countries  FAQ Q: Are you a manufacturer or a trading company ? A: We are a professional manufacturer of enameled wire for rewinding in China . Q: how about your company’s annual production capacity? A: Our Company’s annual production are 1200ton/month. Q: How large the scale of your company? A: Our Company covers almost 2,700,000 square meters.and 76 sets included continuous extrusion. Q: How many kind of spools size ? A:PT4, PT10, PT15, PT25, PT35, PT60, PT90, wooden spools PT-500 and etc. Q : What is specifications of enameled wire your company can produce? A: 1.Enameled round wire: 0.10mm-6.00mm 2.Enameled rectangular wire: Side(a): 1mm-10mm, Side(b): 2mm-16mm 3.Kraft paper covered round wire: 1.5mm-5.0mm 4.Kraft paper covered ractangular wire: (a)1.0mm-5.6mm, (b) 2.00-16mm 5.Fiberglass covered round wire:1.00mm-8.00mm 6.Fiberglass covered rectangular wire:(a)1.00mm-5.60mm,(b)2.00mm-16.00mm Q : What’s the temperature-resist grade of your enameled wire? A: We produce the thermal class of enameled wire from class130 to class220

FAQ Q: Are you a manufacturer or a trading company ? A: We are a professional manufacturer of enameled wire for rewinding in China . Q: how about your company’s annual production capacity? A: Our Company’s annual production are 1200ton/month. Q: How large the scale of your company? A: Our Company covers almost 2,700,000 square meters.and 76 sets included continuous extrusion. Q: How many kind of spools size ? A:PT4, PT10, PT15, PT25, PT35, PT60, PT90, wooden spools PT-500 and etc. Q : What is specifications of enameled wire your company can produce? A: 1.Enameled round wire: 0.10mm-6.00mm 2.Enameled rectangular wire: Side(a): 1mm-10mm, Side(b): 2mm-16mm 3.Kraft paper covered round wire: 1.5mm-5.0mm 4.Kraft paper covered ractangular wire: (a)1.0mm-5.6mm, (b) 2.00-16mm 5.Fiberglass covered round wire:1.00mm-8.00mm 6.Fiberglass covered rectangular wire:(a)1.00mm-5.60mm,(b)2.00mm-16.00mm Q : What’s the temperature-resist grade of your enameled wire? A: We produce the thermal class of enameled wire from class130 to class220 Send your inquiry to this supplier

Send Inquiry