Video

1 / 5

2018 Hot Sale Pet Food Extruding Machinery

| Model No. : | DR-65/70/85/90 |

|---|---|

| Brand Name : | DARIN |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

2018 Hot Sale Pet Food Extruding Machinery

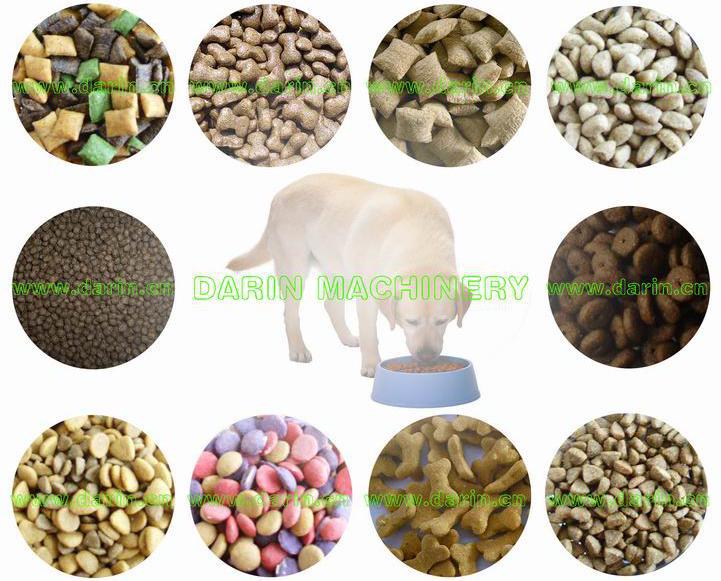

Introduction Pet Food Extruding Line focus on the production of feeds or pets with high nutritional value but low production cost. This line adopts particular process technology, and the final products have fashion shape, special tastes and scientific nutrition.

Features

2018 Hot Sale Pet Food Extruding Machinery has balancing the components and gentle processing are at the center of the related quality considerations.

2018 Hot Sale Pet Food Extruding Machinery is therefore increasingly proving to be the right tool for modern Pet food. A complete feed, fed as a diet over a prolonged period of time, must ensure the vitality of the animal and prevent deficiencies.

2018 Hot Sale Pet Food Extruding Machinery is quite a challenge to the feed manufacturer in terms of the selection and composition of the raw materials, their optimal processing, and effective quality assurance.

2018 Hot Sale Pet Food Extruding Machinery constitute the biggest market segment.

2018 Hot Sale Pet Food Extruding Machinery has high-grade complete feeds capable of maintaining the health even of exotic species in aquariums over prolonged periods of time, sinking or floating feed.

Technicial Parameter

|

Model |

DR-65 |

DR-70 |

DR-85 |

DR-90 |

|

Capacity |

120-150kg/hr |

200-300kg/hr |

500-600kg/hr |

800-1000kg/hr |

|

Power |

80kw |

90kw |

150kw |

200kw |

|

Dimension |

18 x 5 x 3m |

20 x 5 x 3m |

35 x 5 x 3m |

40 x 5 x 3m |

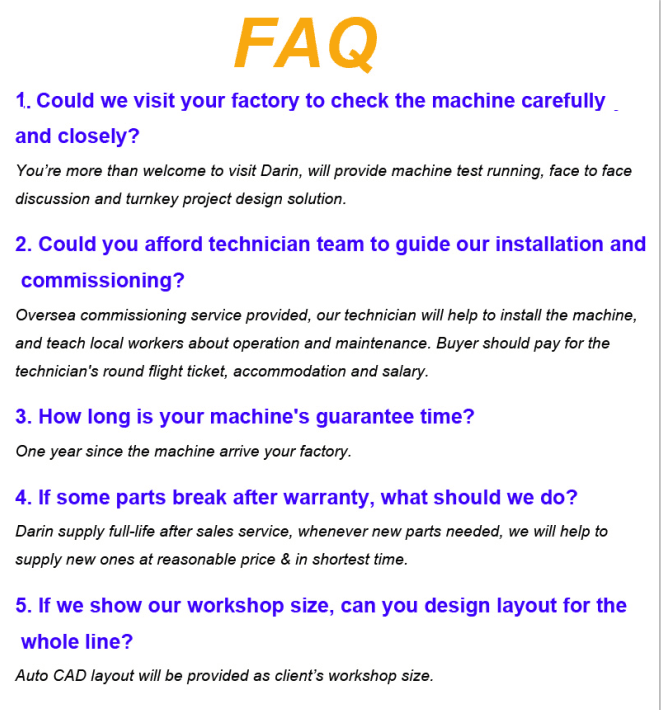

Commissioning & After-sales Service

1. We make accurate factory layout design according to customer`s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker`s restroom, etc.

2. After delivering machines to client`s factory, we start to apply for the Visa to client`s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4. Our engineers have responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

5. It normally costs 10 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

6. The engineer`s round-trip flight tickets, accommodation and daily salary USD100 are on client`s account.

Standard Configuration

|

Item |

Brand |

|

Motor |

WEG or Siemens |

|

Electric Parts |

ABB or Schneider |

|

PLC and Touch Screen |

Siemens (controls whole line, not one or two single equipment) |

|

Bearing |

NSK |

|

Materials |

cover body, mesh belt and parts touching with raw materials or final products are stainless steel |

Certificates

Sample Picture

Picture of Processing Line

Manufacturing

Package & Shipping

FAQ

Contacts

Video

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier