1 / 5

2015 Newly disk mill for factory

| Model No. : | disk mill for factory |

|---|---|

| Brand Name : | MS |

Product description

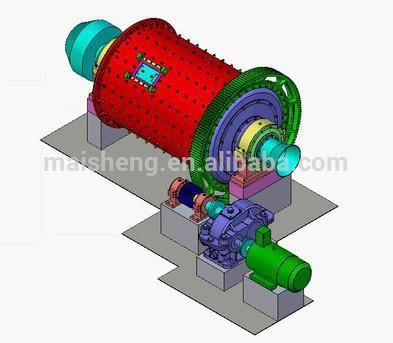

1.Application :2015 Newly disk mill for factory 2015 Newly disk mill for factory is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material.

1.Application :2015 Newly disk mill for factory 2015 Newly disk mill for factory is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material.  2. How to Improve Capacity :2015 Newly disk mill for factory Our 2015 Newly disk mill for factory can satisfy different requirement, and have good features such as low consumption, high capacity per hour, no pollution to the enviroment around, easy to be repaired. We have the good service to our customers, if they can't install the machines, we can send our technician come to your location, and install for you. We make every endeavor to satisfy our customers.

2. How to Improve Capacity :2015 Newly disk mill for factory Our 2015 Newly disk mill for factory can satisfy different requirement, and have good features such as low consumption, high capacity per hour, no pollution to the enviroment around, easy to be repaired. We have the good service to our customers, if they can't install the machines, we can send our technician come to your location, and install for you. We make every endeavor to satisfy our customers.  3 Features of Ball Mill:2015 Newly disk mill for factory 1) is an efficient tool for grinding many materials into fine powder.

3 Features of Ball Mill:2015 Newly disk mill for factory 1) is an efficient tool for grinding many materials into fine powder.2) The ball mill is used to grind many kinds of mine and other materials, or to select the mine

3) Ball mill is widely used in building material, and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

5) Ball mill can be divided into tabular type and flowing type according to differentexpelling mine

6) To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs. 10) Our ball mills have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals. 2015 Newly disk mill for factory 4 Structure:2015 Newly disk mill for factory

Ball mill is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control. 5.Working Principle :2015 Newly disk mill for factory The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials.

Ball mill is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control. 5.Working Principle :2015 Newly disk mill for factory The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials.

6 Technical Parameters:2015 Newly disk mill for factory

6 Technical Parameters:2015 Newly disk mill for factory Model | Cylinder rotary speed(r/min) | Loading ball weight(t) | Input size (mm) | Discharge size(mm) | Capacity (t/h) | Motor power (kw) | Weight (t) |

Ø900×1800 | 39 | 1.5 | ≤20 | 0.075-0.89 | 0.8-2 | 18.5 | 4.6 |

Ø900×3000 | 39 | 2.7 | ≤20 | 0.075-0.89 | 1-4 | 22 | 5.6 |

Ø1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Ø1200×4500 | 32 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

Ø1500×3000 | 27 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

Ø1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

Ø1830×3000 | 25 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

Ø1830×6400 | 24 | 21 | ≤25 | 0.074-0.4 | 7-16 | 210 | 34 |

Ø1830×7000 | 24 | 23 | ≤25 | 0.074-0.4 | 8-18 | 245 | 36 |

Ø2100×3600 | 23 | 19 | ≤25 | 0.074-0.4 | 10-36 | 210 | 46 |

Ø2200×4500 | 21 | 27 | ≤25 | 0.074-0.4 | 12-23 | 280 | 48.5 |

Ø2200×6500 | 21 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

Ø2200×7000 | 21 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

Ø2200×7500 | 21 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

Ø2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 18-45 | 320 | 65 |

Ø2400×8000 | 20 | 36 | ≤25 | 0.074-0.4 | 20-48 | 410 | 81 |

Ø2700×3600 | 21 | 39 | ≤25 | 0.074-0.4 | 19-75 | 400 | 83 |

Ø2700×4000 | 20 | 40 | ≤25 | 0.074-0.4 | 20-78 | 400 | 85 |

Ø2700×4500 | 20 | 48 | ≤25 | 0.074-0.4 | 22-85 | 430 | 89 |

Ø3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | 29-140 | 800 | 137 |

Ø3200×5400 | 18 | 81.6 | ≤25 | 0.074-0.4 | 30-180 | 800-1000 | 146 |

Ø3600×4500 | 17 | 88 | ≤25 | 0.074-0.4 | 35-210 | 1000 | 190 |

Ø3600×6000 | 17 | 117 | ≤25 | 0.074-0.4 | 38-240 | 1250-1500 | 220 |

Ø3600×8500 | 17 | 144 | ≤25 | 0.074-0.4 | 45-260 | 1800 | 260 |

Packaging & Shipping Packaging

Packaging & Shipping Packaging  Our Services Our Services 1.Pre-sales Service

Our Services Our Services 1.Pre-sales Service◆Offering comprehensive technical and business consultation services;

◆Proposing the most suitable scheme and equipment for our clients; ◆Designing and fabricating targeted products according to the special requirements of clients;

◆Training periodically high qualified service technician. 2.After-sales Service

◆Highly inspecting equipments in every working procedure, quality comes first

◆Fast & Safe Delivery

◆Assisting our clients for foundation construction of equipments

◆Dispatching engineers to install and debug equipments

◆Training the first-line operators on site

◆Regularly visit clients to solve production problems

◆Providing life-long maintenance service

◆Providing technical exchanging Company Information Our company 2015 Newly disk mill for factory

FAQ FAQ 2015 Newly disk mill for factory 2015 Newly disk mill for factory In order to save your time ,can you tell me the following time below before send us the inquiry so that we can give you a more suitable quotation and improve our efficiency . 1. What is your raw material to be grind? Iron ore, gold ore, copper ore, or others. 2. What is the maximum feed size of your raw material?

FAQ FAQ 2015 Newly disk mill for factory 2015 Newly disk mill for factory In order to save your time ,can you tell me the following time below before send us the inquiry so that we can give you a more suitable quotation and improve our efficiency . 1. What is your raw material to be grind? Iron ore, gold ore, copper ore, or others. 2. What is the maximum feed size of your raw material? 3. What are output sizes you want?Usually for the mineral processing 60% 200mesh, for the cement grinding 350mesh.

4. What is capacity you want? How many ton per hour? Wet type or dry type? 5. Are you the end user or will you re-sell the machinery to your clients?

If you want to know more detail information about ball mill ,ball mill (dry),rod mill ,super-fine grinding mill ,energy saving ball mill,please connect us at any time.

....

.... Send your inquiry to this supplier