1 / 5

1L Small Volume Chemical Jacketed Stirred Glass Reactor

| Model No. : | S-1L |

|---|---|

| Brand Name : | ZZKD |

| Power Supply : | 220V/50HZ |

Zhengzhou, Henan, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

1L Small Volume Chemical Jacketed Stirred Glass Reactor

Product Description:

The chemical jacketed stirred glass reactor is designed double-level glass.The reaction material is put into the inner, which can be stirred. In the with the different cold and hot medium(refrigetating fluid,hot water and hot oil),do some heat circulations and cooling reactions.Under the constant temperature and ordinary pressure,as well as negative pressure ,stirring reaction can be done in seal glass reactor,also back-flow, distillation etc.

It is widely used in modern refined chemical, biological pharmacy, new material synthesis industry research experiment,etc.

Constant Speed, Pressure and Temperature.

Operation principle of jacketed glass reactor:

Double-glazed designed glass reactor, the liner is for reaction solvent, and the jacket for heating or cooling resource(cool liquid, hot water or hot oil), to achieve circulating heating or cooling experiment. And its ancillary equipment-High and low temperature machine which can satisfy functional high & low temp reaction experiments.

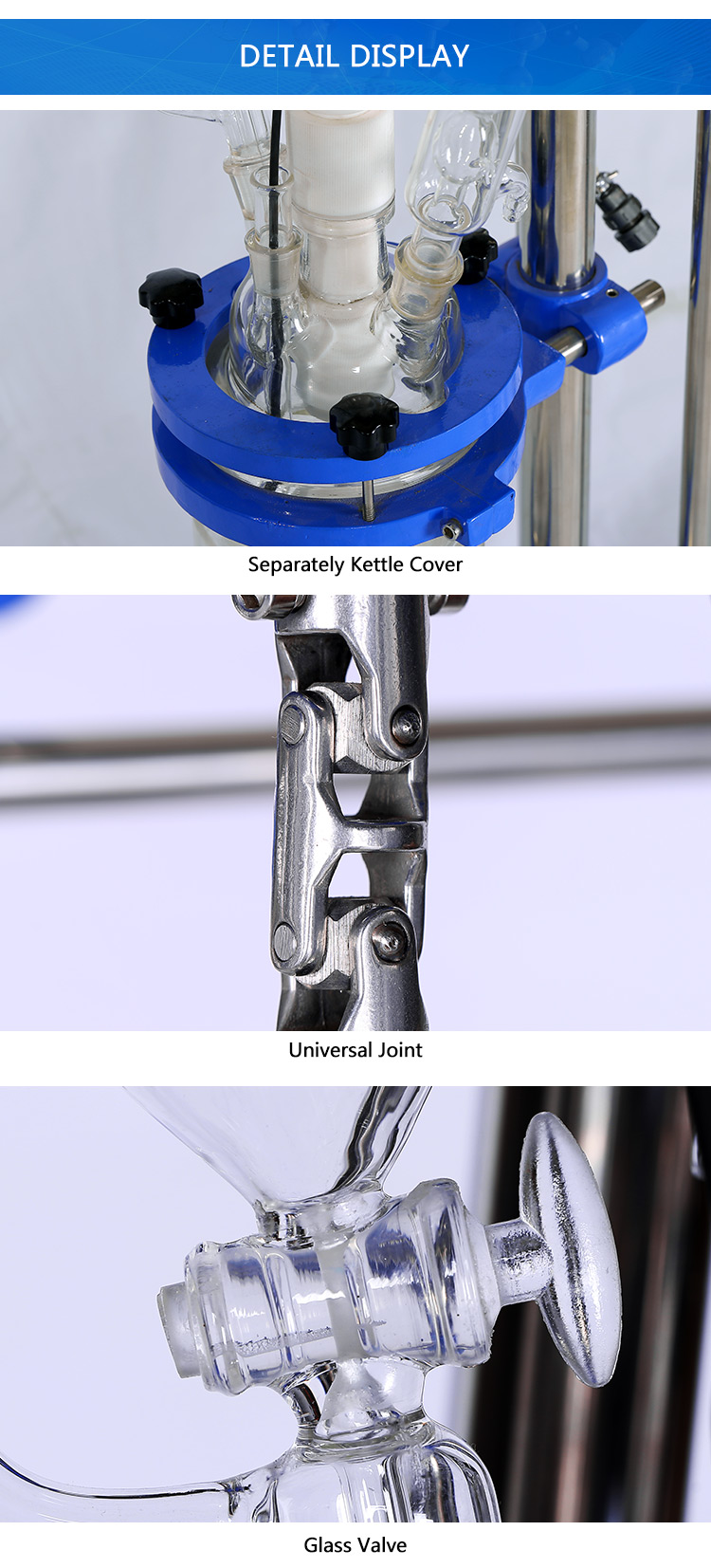

Features of Vacuum Jacketed Glass Reactor:

- Frequency control speed gear motor, smooth running. High torque, no spark,noise free, long life.

- The cover is easy to disassemble, clean and install.

- Stirring mechanical sealing, keeps high vacuum degree.

- Glass(PTFE)discharge valve, (without dead corner,)no dead angle mixing, fast emptying, no residue.

- GG17 high borosilicate glass, resistance to strong acidic substance, exiperiment temperature -80°C to 250°C.

- LCD display, easier and more convenient to measure temperature

- Overall stainless steel frame structure, compact, stable and reliable, without shaking

- LCD display, easier and more accurate to measure temperature

- With brake casters, convenient and reliable for moving.

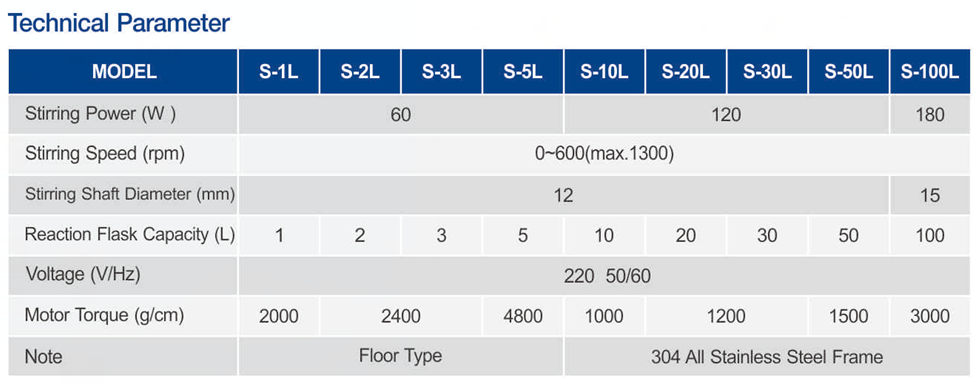

Other Sizes You Can Choose At Your Wish:

Ancillary Equipment of Jacketed glass reactor:

The products can be made into system devices with circulating water vacuum pump, circulating cooler, constant temperature circulator, and heating circulating equipment.

1. Circulating water vacuum pump(Desktop type or Vertical type):

- Providing a vacuum distillation condition.

- Providing low temperature liquid for condensation.

3. Circulating water/oil bath:

- Heating device.

4. High and low temperature all-in-one device:

- Heating and cooling device.

FAQ:

1. What's the max temperature?

Usually the high borosilicate glass can withstand over 300 degree centigrade and the PTFE stirring bar can withstand about 200℃.

2. What's the size do you have?

We can offer you 1L,2L,5L, 10L, 20L, 30L, 50L, 100L,150L.

3. How many kinds of your glass reactor?

Two types: jacketed glass reactor and single layer glass reactor.

Explosion proof is available.

4. What`s the heating mode of single layer glass reactor?

Oil/water bath heating, and heating mantle.

5. Can you offer the supporting facilities?

Yes, we can offer you the vacuum, heating and cooling system as you demand.

6. How will package glass equipment?

We package these glass equipment in good and Non fumigation standard wooden case.

Packing and shipping:

- The glass parts will be wrapped with foam, then put into the carton; the mainbody portion will be packde in wooden case.

- We can ship the goods to you by international express,such as DHL, UPS, TNT and so on. And you can choose the appropriate way based on your timeline and budget. Besides, you can choose to use your own shipping agent.

Our company:

Our main products:

We are confident in providing professional products and service you want,

Please send your inquiry details to us.

Zhengzhou, Henan, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier