1 / 1

1325 Automatic Loading Unloading Cnc Router Nesting Machine

| Model No. : | JX1325 |

|---|---|

| Brand Name : | JINGXUN |

| status : | New |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

1325 Automatic Loading Unloading Cnc Router Nesting Machine

Overview:

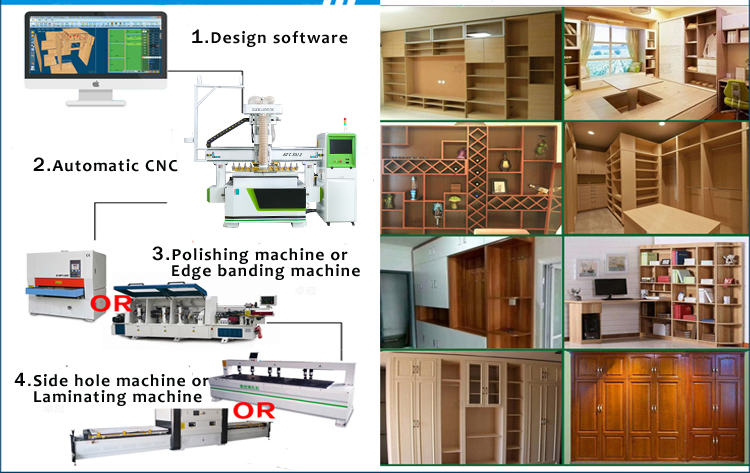

Panel furniture is divided into two types: cabinet body and door panel. These two types can depend on your own situation. The cabinet body mainly includes cutting, drilling three-in-one holes, sealing edges, and assembling. The door panel is relatively simple, mainly for modeling, cutting and polishing, coating, and hinge holes. Generally use ATC cnc router for modeling and cutting. At present, CNC Furniture Nesting Cutting Router Machine is able to cut, as long as the board is not too bad and lint-free, the polishing step can be omitted, and the film is directly covered, and then the hinge hole is made with a hinge machine. A panel furniture factory usually needs a CNC cutting machine, a fully automatic edge banding machine, a CNC drilling machine, and a vacuum laminating machine. With these four pieces, you can basically open a panel furniture factory.

Technical Parameter:

Machine Function:

1.series nesting cnc router machine

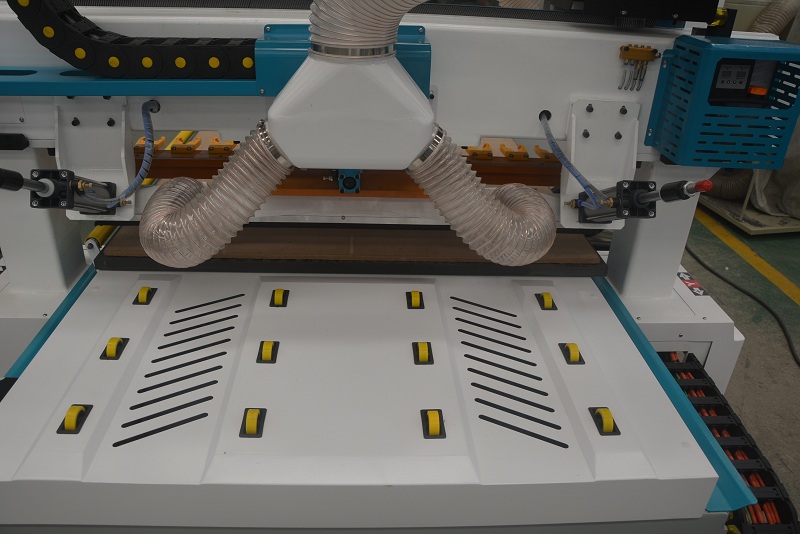

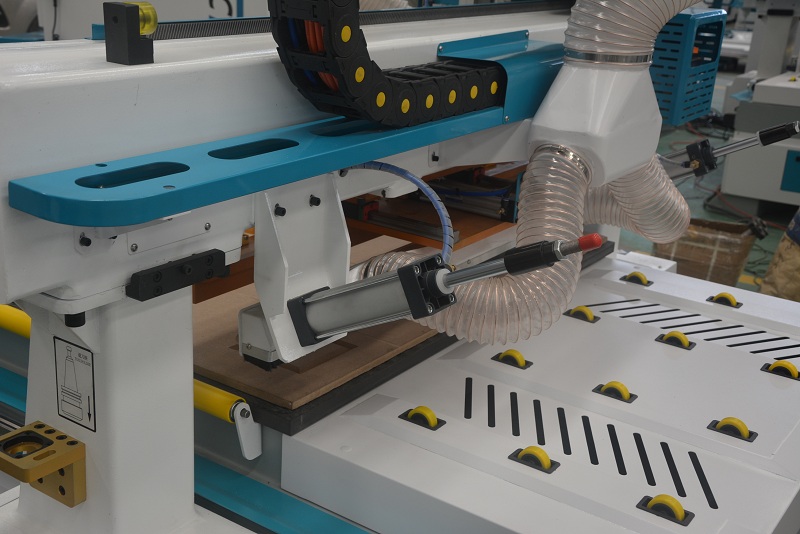

The series has an automatic loading panel lift system, an automatic advance unloading conveyer table, an extremely strong welded steel beam frame with a rotary tool changer on the gantry. The series is extremely fast and allows the operator to simply stand at the end of the unload table and remove cut parts as they unload from the machine.2.The loading lift system allows the operator to load a lift of panels at one time on a heavy steel platform with automatic rise indexing. Using a vacuum cup loading system the machine pulls each panel onto the CNC table for machining while at the same time unloads the previous machined parts and vacuums the machining table clean at the same time. The lift will automatically index the next panel to the correct height for the four 6” vacuum cups to pick it up for the next machining process. The machined parts are pushed onto an automatic advancing conveyer table which senses the panels to be removed. Once the parts at the end of the conveyer are removed by the operator the conveyer will automatically advance the next cut parts to the end of the table and wait for the operator to remove them. An optional printer is available to label parts for tracking throughout the customer’s factory.

3.The base of the machine is a 6000 pound very heavy duty welded steel beam floor model frame. The phenolic vacuum table is then mounted to the steel frame for an excellent working surface and comes with an MDF spoilboard machined at the factory and bolted down to the table. We use plastic bolts to ensure no damage to cutters from contact. The spoilboard is bolted to the table to ensure stability during the loading and unloading process.

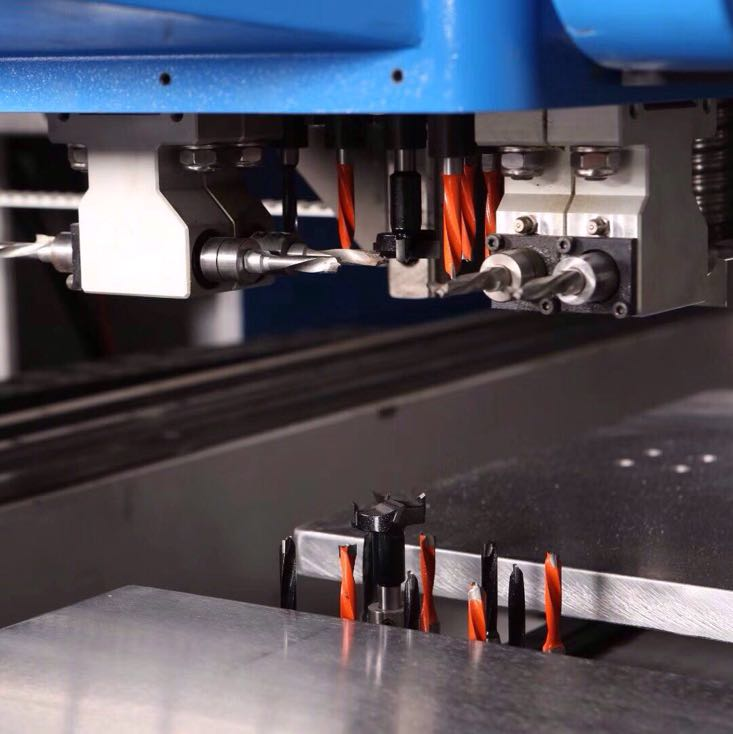

4.Drilling units .(For fast vertical & side drilling works.)

5.Oscillating knife .(For soft material cutting works like foam ,packing box leather etc.)

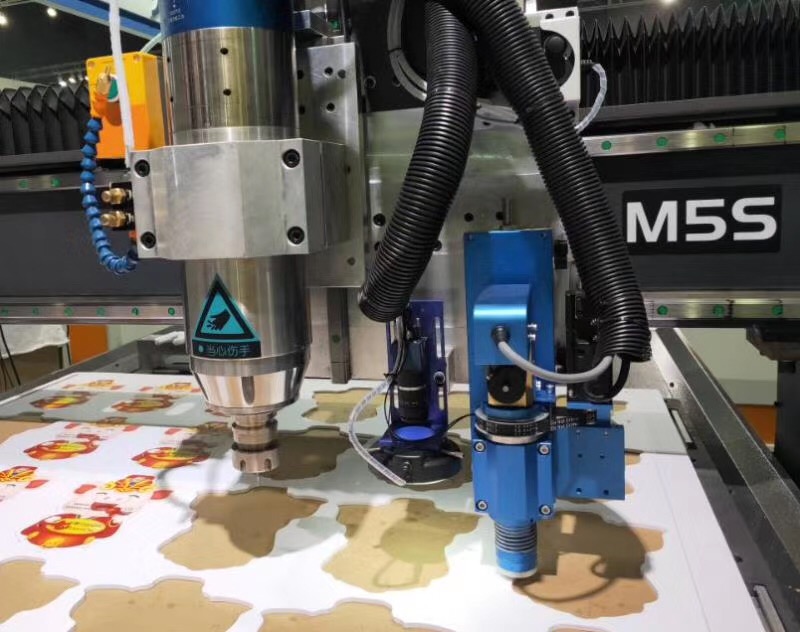

6.CCD camera .(For recognizing the position of graphic during graphic's cutting works.)

Appliable fields:

Applied material & work & industriy

Applied material

1.Non-metal material . Non-metal like wood ,mdf,plywood ,acrylic ,pvc ,foam ,packing boxes etc .

2.Metal material .Aluminum .

Applied work

1.Vertical works are basic .Vertical cutting ,2d or 3d engraving (milling /carving) and drilling are basic functions .

2.Horizontal or angle works or other functions could be optional .We could upgrade the specification according to your needs based on the standard specification like the following optional parts shows ,for example ,if you want to handle the side drilling works via this machine ,we could add a drilling units or a C axis&aggregate head for you ; if you want to cut packing box ,we could add an oscillating knife for you ...

Applied industry

1. Craft & gift industry: engrave various word or graph on the souvenir and handicraft, ironwork engraving, dials.

2. Advertising industry: engrave and cut various signboards, marble, copper, character mold, font. And various metal sign, brand.

3. Wood working industry: mainly used in redwood classical and antique furniture, wood carving, gifts wooden box ,redwood jewelry boxes, ink-stone cutting, decorative products sculpture, fine jewelry carving.

4. Model industry: company plate, signs, building models, emblem, badge, display panels, fair signs, building numbers,

Company site:

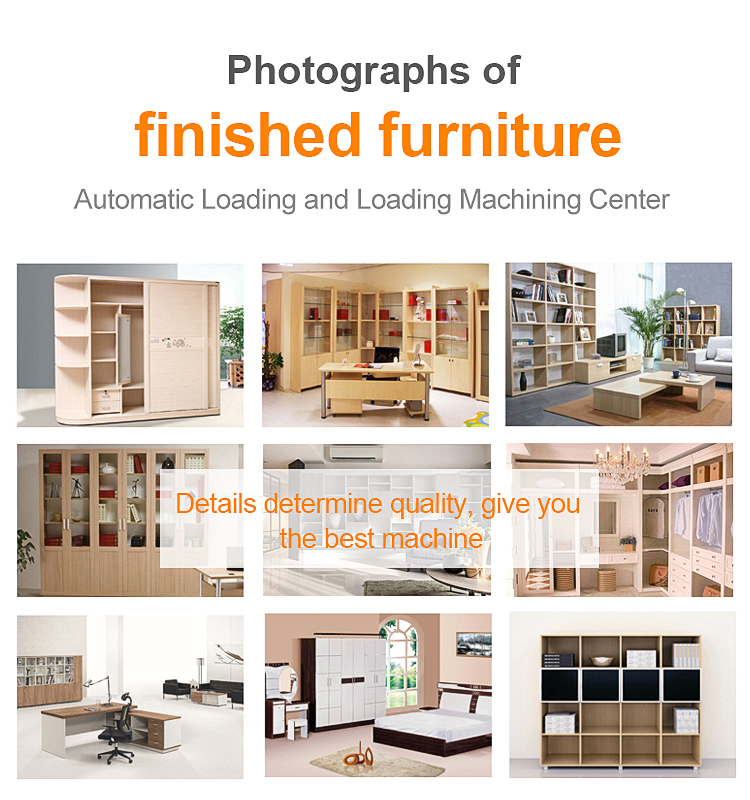

Production Process:

Company team style:

Company Exhibition:

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier